TK Mold - CAD/CAM 软件将交货时间缩短了

70%

单个集成的 CAD/CAM

软件包可减少转换错误、简化设计流程、提高车间效率并缩短工具交付时间

TK Mold & Engineering Inc.

TK Mold & Engineering

Inc.(TK模具与工程公司)

Problem 问题

Ensure the entire team gets the most out of the robust

Cimatron CAD/CAM package to increase overall shop productivity.

确保整个团队充分利用强大的 Cimatron CAD/CAM

软件包,以提高车间的整体生产力。

Solution 方案

Schedule advanced training so everyone, from

estimators to designers to CNC and EDM techs, can use the software more efficiently.

安排高级培训,以便从估算师到设计师再到 CNC 和 EDM

技术人员的每个人都可以更有效地使用该软件。

Results 结果

Continue to increase overall shop productivity,

shorten tool delivery times.

继续提高车间的整体生产力,缩短刀具交付时间。

Romeo, Michigan-based TK Mold & Engineering Inc. was

founded in 2003 by Tom and Krista Barr, who purchased assets and a building that had previously

housed another moldmaker. Tom, who describes himself as a third-generation moldmaker, is

president of TK Mold, and Krista, who is also a licensed master social worker (LMSW), is

director of employee development.

总部位于密歇根州罗密欧的TK Mold &

Engineering Inc.由Tom和Krista Barr于2003年创立,他们购买了资产和一栋以前曾容纳过另一家模具制造商的建筑物。Tom 自称是第三代模具制造商,是 TK

Mold 的总裁,Krista 也是一名持牌社会工作者 (LMSW),是员工发展总监。

“Team culture is very important to both Tom and me,”

explains Krista, who says they actively work to create an environment where all employees have a

voice and feel valued. “We hire quality people, do quality work and provide a quality

experience. We operate our shop with an ‘all hands on deck’ philosophy. Most of our shop

personnel are cross-trained in multiple disciplines and can execute multiple tasks.”

“团队文化对汤姆和我都非常重要,”克里斯塔解释说,她说他们积极努力创造一个让所有员工都有发言权并感到受到重视的环境。“我们雇用高素质的人才,做高质量的工作,并提供高质量的体验。我们以“全员参与”的理念经营我们的商店。我们的大多数车间人员都接受过多个学科的交叉培训,可以执行多项任务。

TK Mold & Engineering 拥有一支由 25 人组成的团队,外加 7 台数控机床、多台车床和钻头以及一台五轴电火花加工机,位于密歇根州罗密欧市的两家工厂,总面积为 25,800 平方英尺/2,397 平方米。

With a team of 25, seven CNC machines, multiple lathes and

drills, and a five-axis sinker EDM housed in two facilities totaling 25,800 square feet/2,397

square meters of space, TK Mold designs tools and parts and builds up to six tools/month. The

company also makes engineering changes and offers maintenance and repairs on anyone’s tools.

Last year, TK Mold added low-volume custom injection molding (up to 50,000 pieces/year) to

ongoing mold sampling services using three presses of 200, 300 and 730 U.S. tons/181, 272 and

622 metric tons. Most mold customers hail from the automotive and consumer goods markets, but

the company also makes tooling for the aerospace and medical segments. Most molded products are

for consumer goods customers.

TK Mold 拥有一支由 25 人组成的团队、7

台数控机床、多台车床和钻头以及一台五轴电火花成形加工机,位于两个总面积为 25,800 平方英尺/2,397 平方米的工厂中,每月设计多达 6

个工具。该公司还进行工程更改,并为任何人的工具提供维护和维修。去年,TK Mold 使用 200、300 和 730 美吨/181、272 和 622

公吨的三台压力机,在正在进行的模具取样服务中增加了小批量定制注塑成型(高达 50,000

件/年)。大多数模具客户来自汽车和消费品市场,但该公司也为航空航天和医疗领域生产模具。大多数模塑产品是为消费品客户准备的。

Over the last two decades, 80% of the company’s tooling

has been produced in steel and the balance in aluminum. During that period, 80% of the tools

were for injection molding (straight injection, two-shot, rotary and pick and place) ranging

from one to eight cavities and frequently with side action. The remaining 20% of production

tooling was for compression molding. Injection tooling is typically sized for presses ranging

from 85 to 730 U.S. tons/77 to 662 metric tons, with the company’s sweet spot falling between

200 and 500 U.S. tons/181 and 454 metric tons. Many of these tools are designed for precision

molding to hold tolerances of ±0.050 millimeter/0.002 inch on the AZ axis of a plastic

fitting.

在过去的二十年里,公司80%的模具都是用钢生产的,其余的都是用铝生产的。在此期间,80%的模具用于注塑成型(直注、双射、旋转和拾取和放置),从1到8个腔体不等,并且经常带有侧面作用。剩下的20%的生产工具用于压缩成型。注塑模具的尺寸通常为

85 至 730 美吨/77 至 662 公吨的冲压机,该公司的最佳压力机介于 200 至 500 美吨/181 至 454 公吨之间。其中许多工具是为精密成型而设计的,以在塑料配件的

AZ 轴上保持 ±0.050 毫米/0.002 英寸的公差。

该公司为汽车、消费品、航空航天和医疗领域的客户制造模具,并为消费品制造注塑模具产品。TK Mold 已通过 ITAR 注册和 ISO 9001:2015 认证。它被评为 2022 年 AMBA 年度模具制造商和 2023 年度开拓者。

Given its customer base, TK Mold is ITAR registered and

ISO 9001:2015 certified. It was named the AMBA Mold Maker of the Year in 2022 and Trail Blazer

of the Year in 2023. Very active in mentoring young people in toolmaking, the company has a

Registered Apprenticeship Program with the U.S. Department of Labor; was named Macomb Career

Technical Education Administrator’s Association Outstanding Business Partner for 2018-2019; and

Romeo High School Business Partner annually from 2019 through 2022. TK Mold also received the

Macomb County Outstanding Business Award in 2021 and Special Congressional Recognition and

Special Senatorial Recognition certificates in 2019.

鉴于其客户群,TK Mold 已通过 ITAR 注册和 ISO

9001:2015 认证。它被评为 2022 年 AMBA 年度模具制造商和 2023

年度开拓者。该公司非常积极地指导年轻人进行工具制造,与美国劳工部签订了注册学徒计划;被评为2018-2019年度马科姆职业技术教育行政人员协会杰出商业合作伙伴;从 2019 年到

2022 年,每年都是罗密欧高中商业合作伙伴。TK Mold 还获得了 2021 年马科姆县杰出商业奖,并于 2019

年获得了国会特别认可和参议院特别认可证书。

Benefits of Integrated CAD/CAM

集成 CAD/CAM 的优势

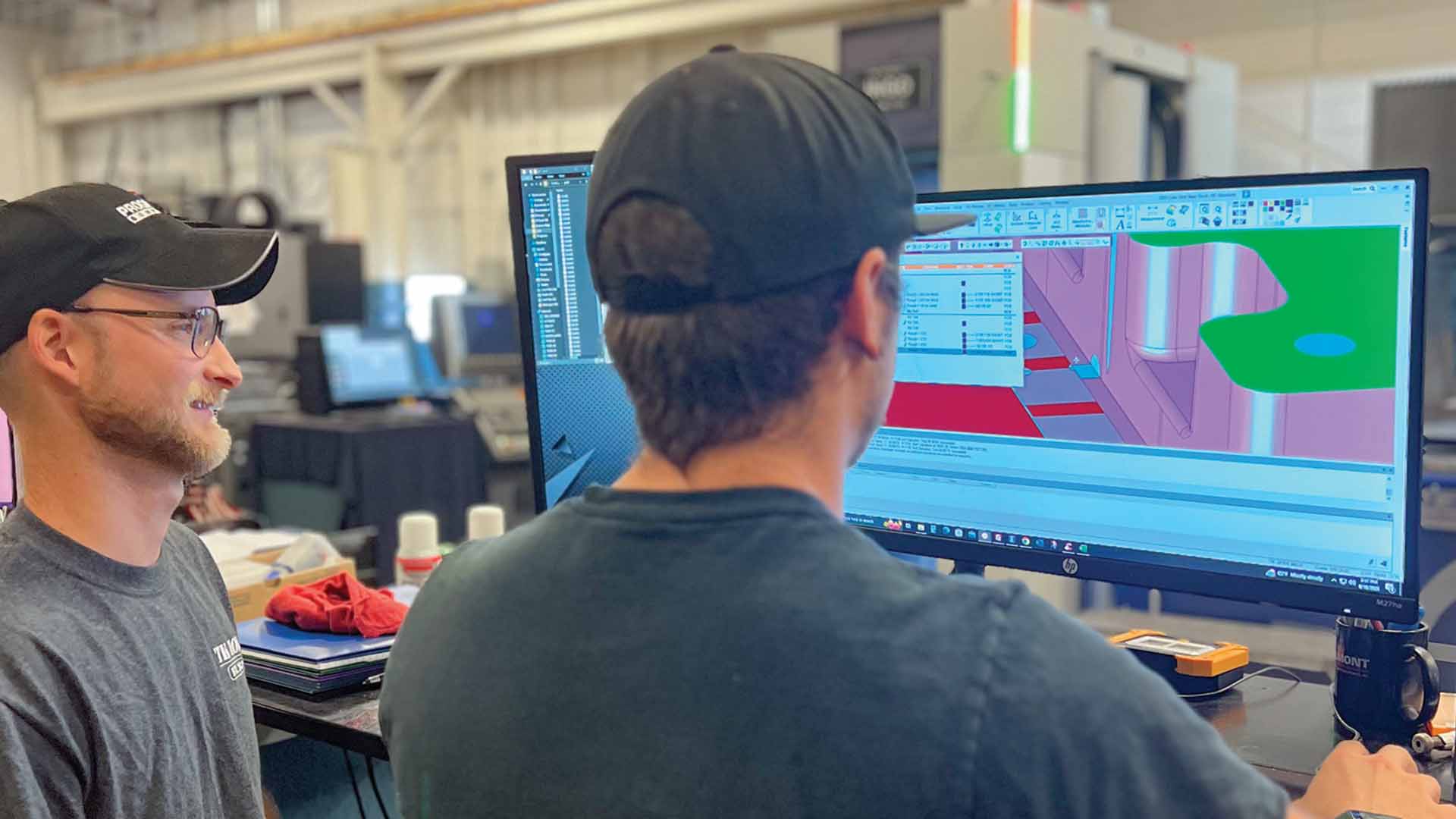

Since its inception, TK Mold has used integrated Cimatron

CAD/CAM software to streamline its workflow from quoting and design straight through to

machining and EDM to assembly. The company currently has 10 licenses: three Cimatron Designer

Solution (CAD), five Cimatron NC Solution (CAM), one EDM Solution (electrode design and

manufacturing) and two floating View Only licenses for personnel operating CNC and EDM machines.

自成立以来,TK Mold 一直使用集成的 Cimatron

CAD/CAM 软件来简化其工作流程,从报价和设计直接到加工和 EDM 再到装配。该公司目前拥有 10 个许可证:3 个 Cimatron Designer 解决方案 (CAD)、5

个 Cimatron NC 解决方案 (CAM)、1 个 EDM 解决方案(电极设计和制造)和 2 个浮动 View Only 许可证,供操作 CNC 和 EDM

机床的人员使用。

“Years ago, we had one guy using a different package, but

we switched exclusively to Cimatron as we found that managing data was much easier when everyone

used the same software, especially for updates,” notes Tom. “This way, we never have translation

issues when moving data between packages. Also, because it was designed for the tool and die

industry, Cimatron is very user-friendly for moldmakers.”

Tom 指出:“几年前,我们有一个人使用不同的软件包,但我们专门改用

Cimatron,因为我们发现,当每个人都使用相同的软件时,管理数据要容易得多,尤其是在更新时。“这样一来,在包之间移动数据时,我们就不会遇到翻译问题。此外,由于Cimatron是为工具和模具行业设计的,因此对模具制造商来说非常人性化。

自成立以来,TK Mold 一直使用集成的 Cimatron CAD/CAM 软件来简化其工作流程,从报价和设计直接到加工和 EDM 再到装配。该公司还定期投资于高级培训,以确保其整个团队充分利用强大的软件。这通过缩短工具交付周期和提高车间生产力而得到了回报。

“The ability to take a part and start making parting lines

with Cimatron’s QuickSplit feature allows us to streamline designs from the time we kick off a

job,” adds Jonathan Salter, TK Mold CNC manager. “Cimatron offers many libraries from all the

major vendors that allow you to design anything from gates to runners to ejector pins with just

a few clicks of the mouse. The tools they’ve incorporated in their software really help with all

aspects of design — from slides and lifters to waterlines and mold bases — and shorten the

amount of time it takes to move from design to production to completion.”

“使用 Ciamtron 的 QuickSplit

功能进行零件并开始制作分型线的能力使我们能够从开始工作时就简化设计,”TK Mold CNC 经理 Jonathan Salter 补充道。“Cimatron

提供了许多来自所有主要供应商的库,只需点击几下鼠标,您就可以设计从浇口到流道再到顶针的任何产品。他们在软件中整合的工具确实有助于设计的各个方面——从滑轨和升降机到水线和模架——并缩短了从设计到生产再到完成所需的时间。

What sets us apart from our competitors is that from the very beginning, our software was developed to address the needs of the tool and die industry.

我们与竞争对手的不同之处在于,从一开始,我们的软件就是为了满足工具和模具行业的需求而开发的。

Designed for Tool and Die

专为工具和模具设计

Cimatron began life in 1982 as an Israeli software company

named Microcad that focused on developing manufacturing software for the country’s Air Force.

Within 2 years, the company introduced its first CAD and CAM packages designed for medium-sized

tool shops. In 1990, the company changed its name to Cimatron Ltd. and introduced its first

integrated CAD/CAM package called Cimatron IT. In 2008, Cimatron merged with CNC machining

software provider Gibbs and Assoc. and added GibbsCAM to its product offering.

Cimatron 成立于 1982 年,是一家名为 Microcad

的以色列软件公司,专注于为该国空军开发制造软件。在 2 年内,该公司推出了第一个专为中型工具车间设计的 CAD 和 CAM 软件包。1990 年,公司更名为 Cimatron

Ltd.,并推出了第一个集成的 CAD/CAM 软件包,称为 Cimatron IT。2008 年,Cimatron 与 CNC 加工软件提供商 Gibbs and Assoc.

合并,并将 GibbsCAM 添加到其产品中。

The joint company collaborated with LEDAS (now LGS 3D) in

2010 to add motion simulation and crash detection capabilities, which were subsequently licensed

and integrated into the package. By 2013, Cimatron was researching additive manufacturing and

developing tools to incorporate conformal cooling into mold designs. In 2015, Cimatron was

acquired by 3D Systems, which sold the company in 2020 to Battery Ventures, which, in turn,

added SigmaNEST software to the product portfolio before an acquisition by Sandvik in 2021.

该合资公司于2010年与LEDAS(现为LGS

3D)合作,增加了运动模拟和碰撞检测功能,随后获得许可并集成到软件包中。到 2013 年,Cimatron 开始研究增材制造和开发工具,将随形冷却纳入模具设计。2015

年,Cimatron 被 3D Systems 收购,3D Systems 于 2020 年将公司出售给 Battery Ventures,后者在 2021 年被山特维克收购之前将

SigmaNEST 软件添加到产品组合中。

Cimatron 开创了许多功能,使模具设计速度更快,例如快速拆分(左上角)、型芯/型腔和滑块/升降器的拆分,以快速检测潜在问题;快速比较(左下角),不同部门的多个团队成员使用一个工具时,新旧零件数据的数学比较;和快速电极(右中),随着刀具几何形状的设置,自动电极设计和刀具路径生成。

“What sets us apart from our competitors is that from the

very beginning, our software was developed to address the needs of the tool and die industry,”

explains Ralph Picklo, Cimatron Americas sales director. “If you’re designing molds, dies,

fixtures or gages, why wouldn’t you use integrated, efficient, user-friendly software dedicated

to designing and producing the very things you’re building every day?”

“我们与竞争对手的不同之处在于,从一开始,我们的软件就是为了满足工具和模具行业的需求而开发的,”Cimatron

美洲销售总监 Ralph Picklo 解释道。“如果您正在设计模具、夹具或量具,为什么不使用集成、高效、用户友好的软件来设计和生产您每天建造的东西呢?”

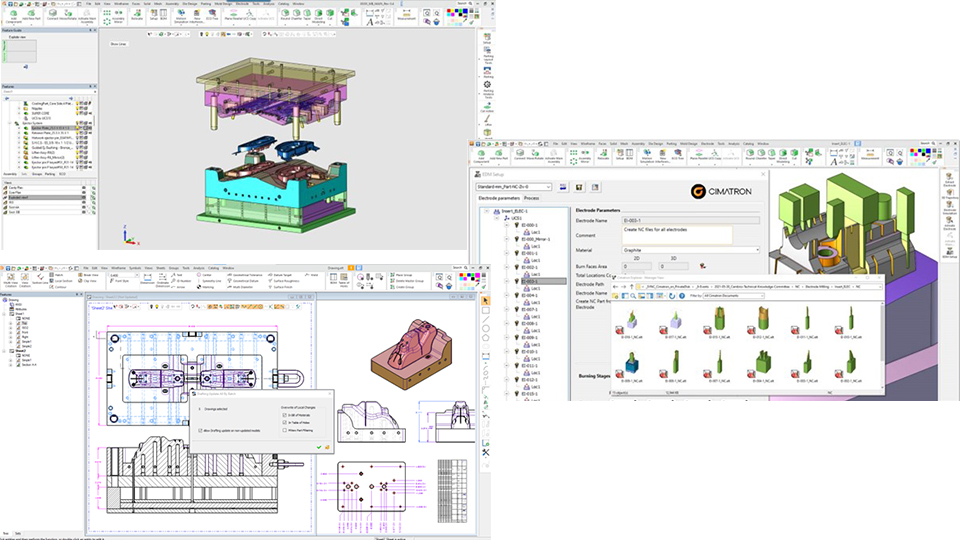

He adds that most major software packages used in the

plastics industry offer CAD or CAE or process simulation but aren’t integrated with CAM, and the

handful that do offer CAD/CAE/CAM still don’t have specific tools to design and manufacture

molds efficiently. With Cimatron, the entire mold design and production functions are fully

integrated, yet the system still offers the flexibility to make last-minute changes. That’s why

the software can help shops reduce tool delivery times by up to 70% and ROI for the software is

typically achieved within 6 months.

他补充说,塑料行业使用的大多数主要软件包都提供CAD或CAE或工艺模拟,但没有与CAM集成,少数提供CAD/CAE/CAM的软件包仍然没有特定的工具来有效地设计和制造模具。使用Cimatron,整个模具设计和生产功能完全集成,但该系统仍然提供了在最后一刻进行更改的灵活性。因此,该软件可以帮助车间将工具交付时间缩短多达

70%,并且该软件的投资回报率通常在 6 个月内实现。

“Thanks to our digital connectivity, templating, a

standard mold component catalog and direct integration with the CoroPlus Tool Library and TDM

tool management system, as well as automation of repetitive processes, Cimatron makes the design

process more efficient from the very start,” Picklo continues. “In fact, it enables a designer

to specify a company’s standards and then apply them to every job so they don’t have to reinvent

the wheel each time.” He says that as tool delivery times keep getting shorter, companies need

software that’s dedicated and streamlined for their industry. “Our software allows multiple

users in different departments to work on the same job at the same time, drastically shortening

tool delivery times while ensuring all users work with the most current data while tracking all

of the engineering changes.” Once the tool is designed, CAM files are produced and then

converted to G-code to rough and finish mill in two-, three- and five-axis CNC machines.

Additionally, the software generates files to burn electrodes on sinker EDMs without manual

input.

“得益于我们的数字连接、模板、标准模具组件目录以及与CoroPlus刀具库和TDM刀具管理系统的直接集成,以及重复过程的自动化,Cimatron从一开始就使设计过程更加高效,”Picklo继续说道。“事实上,它使设计师能够指定公司的标准,然后将它们应用于每项工作,这样他们就不必每次都重新发明轮子。他说,随着工具交付时间的不断缩短,公司需要为其行业专用和简化的软件。“我们的软件允许不同部门的多个用户同时从事同一工作,大大缩短了工具交付时间,同时确保所有用户都能使用最新数据,同时跟踪所有工程变更。”一旦工具设计完成,就会生成

CAM 文件,然后转换为 G 代码,以便在两轴、三轴和五轴 CNC

机床中进行粗铣和精铣。此外,该软件还可以生成文件,无需手动输入即可在电火花成形加工机上燃烧电极。

A good example of how Cimatron automates and speeds the

design process is an automotive mold TK Mold’s team recently completed. “Upon kicking off a job,

many of our customers give us a range of different press sizes a mold may go into, which allows

us to change mold base sizes to find the one that best fits our customer’s needs,” explains

Salter. “Cimatron enables us to easily apply mold bases in our design directly from a drop-down

menu, rather than requiring us to go to the websites of mold base suppliers and download a CAE

model for each mold base we think we might need and then manually load it into our CAD package.

Features like that really simplified things on this challenging job with a short lead time and

many engineering changes. We were able to switch between mold bases of different sizes without

having to input more information from external sites.”

Cimatron 如何自动化和加速设计过程的一个很好的例子是 TK

Mold 团队最近完成的汽车模具。“在开始工作时,我们的许多客户都会向我们提供一系列不同的压机尺寸,这使我们能够更改模架尺寸,以找到最适合客户需求的模架尺寸,”Salter

解释道。“Cimatron 使我们能够直接从下拉菜单轻松地将模架应用到我们的设计中,而不需要我们访问模架供应商的网站,为我们认为可能需要的每个模架下载一个 CAE

模型,然后手动将其加载到我们的 CAD

包中。像这样的功能确实简化了这项具有挑战性的工作,交货时间短,工程变更也很多。我们能够在不同尺寸的模架之间切换,而无需从外部站点输入更多信息。

由于 Cimatron 是专为工具和模具行业设计的完全集成的 CAD/CAM 软件包,因此它可以帮助设计师和机床操作员设计机床功能,例如多个高度的多个型腔(左上)、用于铣削的五轴倾斜(左下)以及增材制造刀片中的自动或定制随形冷却通道(右)。

Staying Ahead of the Game With Advanced Training

通过高级培训保持领先地位

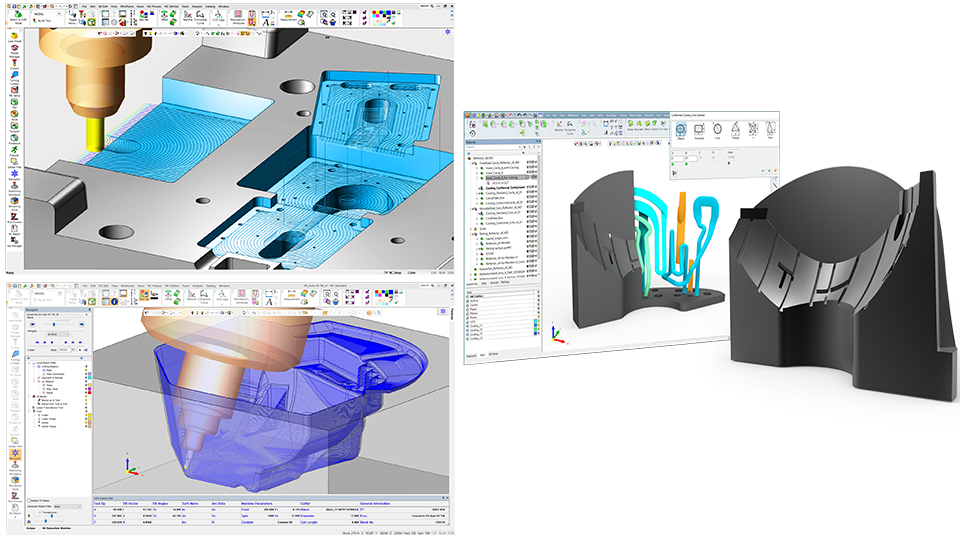

Despite using Cimatron for two decades, TK Mold

periodically takes the time and invests in having the supplier come in to conduct advanced

training, especially as new features are added to the software.

尽管使用 Cimatron 已有二十年之久,但 TK Mold

会定期花时间并投资让供应商进行高级培训,尤其是在软件中添加新功能时。

“While you can start using it right away, given how robust

Cimatron is, it does take time to master the software,” adds Tom. “To maximize our effectiveness

and keep shortening our tool delivery lead times, we make it a practice to bring Cimatron in to

conduct advanced training for our team and this investment really pays off by allowing us to use

the software more efficiently with each major upgrade. The best part of this extra training is

that it allows us to ask questions about our processes and tools we’re currently working

on.”

“虽然您可以立即开始使用它,但考虑到 Cimatron

的强大功能,掌握该软件确实需要时间,”Tom

补充道。“为了最大限度地提高我们的效率并不断缩短我们的工具交付周期,我们采用Cimatron为我们的团队进行高级培训,这项投资确实得到了回报,使我们能够在每次重大升级时更有效地使用软件。这种额外培训最好的部分是,它允许我们询问有关我们目前正在使用的流程和工具的问题。

“Tom and Krista always want to take advantage of the

latest technology, so they’re willing to invest in advanced training sessions that move their

team from average users to pro users, which really streamlines their process and makes their

shop more profitable,” says Picklo, who adds that this should be a lesson to all companies who

want to avoid getting stuck in a rut. “I have customers who’ve told me that if they can knock 1

minute per day off the time it takes each of their 16 designers to accomplish a task, then that

multiplier really adds up to significant time savings at the end of the month. Some shops say

they can’t take the time to do the extra training, but I say to them, they can’t afford not to

take the time.”

“Tom 和 Krista

一直希望利用最新技术,因此他们愿意投资于高级培训课程,将他们的团队从普通用户转变为专业用户,这确实简化了他们的流程,使他们的商店更有利可图,”Picklo

说,他补充说,这应该是所有想要避免陷入困境的公司的一个教训。“我的客户告诉我,如果他们每天能将 16 位设计师中每个人完成一项任务所需的时间缩短 1

分钟,那么这个乘数确实可以在月底节省大量时间。有些商店说他们不能花时间做额外的培训,但我对他们说,他们不能不花时间。