VMR Achieves Fast and Efficient Prototyping with Cimatron

VMR 借助 Cimatron 实现快速高效的原型设计

CHALLENGE 挑战

Efficiently, cost-effectively design and manufacture prototypes and short runs while reducing errors.

高效、经济地设计和制造原型和小批量生产,同时减少错误。

SOLUTION 方案

Cimatron integrated CAD/CAM software for mold design and manufacturing

Cimatron 用于模具设计和制造的集成 CAD/CAM 软件

RESULTS 结果

Reduced electrode design and manufacturing time by 70% and automated the process by defining templates. Operated milling and EDM machines at full capacity to design and produce 10,000 electrodes per year.Eliminated data import errors. Accelerated on-boarding time for new employees (8 days of training).Maximized return on investment.

将电极设计和制造时间缩短了 70%,并通过定义模板实现了流程自动化。铣床和电火花加工机床满负荷运转,每年设计和生产 10,000 个电极。消除了数据导入错误。加快了新员工的入职时间(8 天的培训)。投资回报最大化。

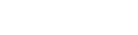

VMR GmbH & Co. KG, located in Mönchweiler in southern Germany, has a wide range of machines, from CNC milling and EDM machines; to mill/turn, vacuum, and die-casting machines; to metal and plastic 3D printers. “We focus on prototypes and short runs of up to 10,000 parts,” explains CEO Thomas Viebrans. “We offer our customers a broad range of manufacturing technologies from one provider.” Each day brings different customers and different challenges that require an extremely flexible and efficient CAD/CAM system. With Cimatron, VMR designs and manufactures up to 50 graphite electrodes per day (10,000 per year).

VMR GmbH & Co. KG 位于德国南部的 Mönchweiler,拥有各种机床,包括 CNC 铣床和电火花加工机床;铣/车床、真空机和压铸机;金属和塑料 3D 打印机。“我们专注于原型和多达 10,000 个零件的短期运行,”首席执行官 Thomas Viebrans 解释道。“我们为客户提供来自一家供应商的广泛制造技术。”每天都有不同的客户和不同的挑战,需要极其灵活和高效的 CAD/CAM 系统。借助 Cimatron,VMR 每天可设计和制造多达 50 个石墨电极(每年 10,000 个)。

Implementing a Seamless Workflow from Idea to Final Product

实现从构思到最终产品的无缝工作流程

VMR has customers in multiple industries including automotive, aerospace, and medical. The company supports the entire process from design and NC programming to production and assembly. VMR also provides customers with customized mold design and optimization.

VMR 的客户遍及多个行业,包括汽车、航空航天和医疗。该公司支持从设计和数控编程到生产和装配的整个过程。VMR还为客户提供定制化的模具设计和优化。

Since 2000, their tool of choice is Cimatron integrated CAD/CAM software. Previously, VMR used STRIM 100 and Euclid Styler software for CAD and SolidCAM software for CAM,

自 2000 年以来,他们选择的工具是 Cimatron 集成的 CAD/CAM 软件。以前,VMR 使用 STRIM 100 和 Euclid Styler 软件进行 CAD,使用 SolidCAM 软件进行 CAM,

which frequently caused data translation errors. Viebrans remembers: “We had to reject orders because we couldn’t open the models from customers. In addition, the system wasn’t geared towards toolmaking and the CAM license was really expensive.”

这经常导致数据转换错误。Viebrans 回忆道:“我们不得不拒绝订单,因为我们无法打开客户的模型。此外,该系统不适合工具制造,而且 CAM 许可证非常昂贵。

VMR车间

Because of these issues, they started evaluating a new CAD/CAM solution in 1999. VMR tested various systems and Cimatron soon stood out as a favorite, largely because it is an integrated system. Viebrans says: “We liked the openness and the comprehensiveness of the system. The previous system offered very good freeform modeling, but Cimatron was even better. One of the real highlights of Cimatron is the CAD data interfaces, which are affordable and of premium quality.”

由于这些问题,他们于 1999 年开始评估新的 CAD/CAM 解决方案。VMR 测试了各种系统,Cimatron 很快脱颖而出,成为最受欢迎的系统,主要是因为它是一个集成系统。Viebrans 说:“我们喜欢系统的开放性和全面性。以前的系统提供了非常好的自由曲面建模,但 Cimatron 甚至更好。Cimatron 的真正亮点之一是 CAD 数据接口,它价格实惠且质量上乘。

VMR now has fewer interface issues with no data errors caused by import and export, which ensures a higher throughput and process-proof planning.

VMR 现在的接口问题更少,不会因导入和导出而导致数据错误,从而确保更高的吞吐量和流程安全规划。

Cimatron proves its value every day. For example, VMR has more than 20 view-only licenses, which are used on the shop floor by machinists who can then view the 3D models and figure out how to assemble the tools. This not only makes the machinists’ work easier, it also makes the designers’ work easier because they have to answer fewer questions. Sales and other departments also use the view-only licenses.

Cimatron每天都在证明它的价值。例如,VMR 拥有 20 多个仅供查看的许可证,机械师可以在车间使用这些许可证,然后他们可以查看 3D 模型并弄清楚如何组装工具。这不仅使机械师的工作更轻松,还使设计师的工作更轻松,因为他们必须回答更少的问题。销售部门和其他部门也使用仅查看许可证。

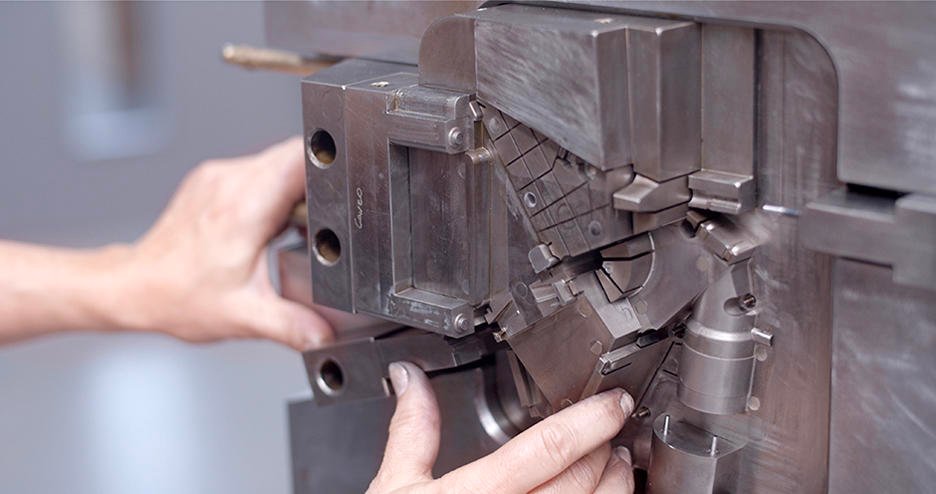

QuickSplit 在 Cimatron® 中设计的零件的实际应用

在Cimatron®设计模具

Since we started using Cimatron, we have never experienced problems with data import again. In addition, the follow-up and maintenance costs are affordable.

自从我们开始使用 Cimatron 以来,我们再也没有遇到过数据导入问题。此外,后续和维护费用是可以承受的。

Thomas Viebrans,VMR GmbH & Co. KG 首席执行官

Automating Electrode Design for High Output

自动化电极设计,实现高输出

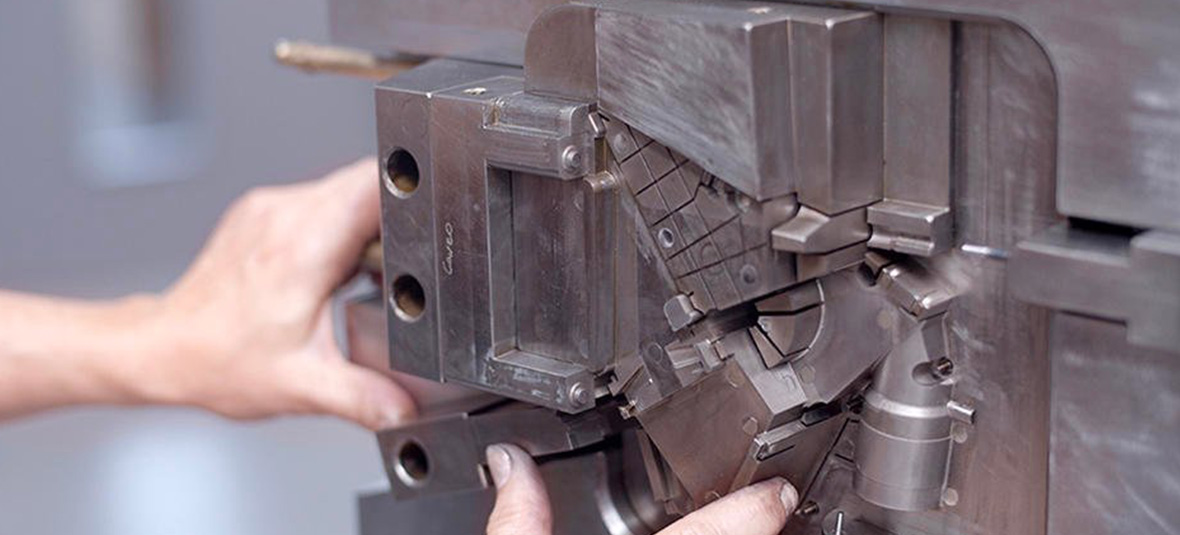

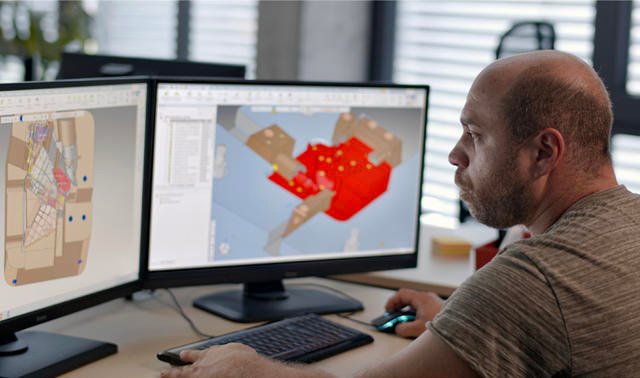

VMR reduced the time it takes to design and manufacture electrodes by 70 percent and automated the process by defining templates in Cimatron for the most-used electrode geometries. These templates are predefined with all parameters for design and production such as with NC programs for milling. A new electrode is generated by choosing the most suitable template and editing the geometry. After Cimatron has refreshed the model, VMR can start production immediately.

VMR 将设计和制造电极所需的时间缩短了 70%,并通过在 Cimatron 中为最常用的电极几何形状定义模板来自动化流程。这些模板预定义了用于设计和生产的所有参数,例如用于铣削的 NC 程序。通过选择最合适的模板并编辑几何形状来生成新电极。Cimatron 刷新模型后,VMR 可以立即开始生产。

在Cimatron中加载预定义的模板,并具有用于计算目的的标准

Last year, our electrode engineers generated geometry and NC programs for 10,000 electrodes, which is about 50 electrodes per day. This is only possible with reliable and extraordinary automation. Cimatron offers exactly that. With Cimatron, we can operate our milling and EDM machines at full capacity.

去年,我们的电极工程师为 10,000 个电极生成了几何形状和 NC 程序,即每天大约 50 个电极。这只有通过可靠和非凡的自动化才能实现。Cimatron 正是提供了这一点。有了Cimatron,我们可以满负荷运行我们的铣床和电火花加工机床。

Thomas Viebrans,VMR GmbH & Co. KG 首席执行官

Viebrans adds: “It helps that our engineers have worked as NC programmers, so they know the pitfalls. The 3D models are built in a way that makes CAM easy—at a rate of 50 per day, this is a critical factor.”

Viebrans 补充道:“我们的工程师曾担任 NC 编程人员,因此他们知道其中的陷阱,这很有帮助。3D 模型的构建方式使 CAM 变得简单——以每天 50 个的速度,这是一个关键因素。

Maximizing ROI 最大化投资回报率

Cimatron has enabled VMR to maximize their return on investment (ROI) by increasing efficiency and productivity through automation, accelerating on-boarding time for new employees, and completing more orders.

Cimatron 通过自动化提高效率和生产力、加快新员工入职时间以及完成更多订单,使 VMR 能够最大限度地提高投资回报率 (ROI)。

The ease of use of Cimatron is a significant advantage: “It is easy for new employees to become efficient in Cimatron,” says Viebrans. Cimatron software sales representative Angelika Hermann explains: “Eight days of training are enough to introduce an engineer to Cimatron. VMR is my showcase customer when it comes to efficiency in Cimatron.”

Cimatron 的易用性是一个显著的优势:“新员工在 Cimatron 中很容易变得高效,”Viebrans 说。Cimatron 软件销售代表 Angelika Hermann 解释说:“八天的培训足以让工程师了解 Cimatron。在Cimatron的效率方面,VMR是我的典型客户。

VMR员工学习如何在Cimatron设计和制造模具和电极

“Over the years, Cimatron has been a really valuable partner,” remembers Viebrans. “The training is excellent and enables our employees to work in Cimatron almost immediately. The cooperation with our sales representative was close, pleasant, and relaxed from the start, which is important as it makes business easier and creates confidence.”

“多年来,Cimatron 一直是一个非常有价值的合作伙伴,”Viebrans 回忆道。“培训非常出色,使我们的员工几乎可以立即在Cimatron工作。与我们的销售代表的合作从一开始就是密切、愉快和轻松的,这很重要,因为它使业务更容易并建立信心。

“In our business, speed is crucial”, Viebrans concludes. “Our customers need consistent, high-quality prototypes as fast as possible. To meet these expectations, I need to have trust in our tools; that’s what Cimatron offers me. I would recommend Cimatron to anyone.”

“在我们的业务中,速度至关重要”,Viebrans 总结道。“我们的客户需要尽快获得一致、高质量的原型。为了满足这些期望,我需要信任我们的工具;这就是Cimatron为我提供的。我会向任何人推荐Cimatron。

VMR使用Cimatron设计和制造的最终模具