2elle-engineering SRL

灵活性驱动由2elle-engineering设计的顶级锻造轮毂

Thanks to Cimatron’s capabilities, we can easily extract the internal geometry, set suitable thicknesses, instantly change profiles, and try other solutions. Generally, once the design is set up, most of the work is already done because the changes are quick to implement.

借助 Cimatron 的能力,我们可以轻松提取内部几何形状、设置合适的厚度、立即更改轮廓并尝试其他解决方案。通常,一旦设计设置好,大部分工作就已经完成,因为更改可以快速实现。

Davide Lucaora,2elle-engineering Srl 技术/生产经理

The ability to swiftly engage with customer aspirations while maintaining premium quality sets 2elle-engineering apart in the world of forged metal wheels. Designing with a flexible and efficient CAD software plays a pivotal part.

在保持优质品质的同时,能够迅速满足客户的愿望,使2elle-engineering在锻造金属轮毂领域脱颖而出。使用灵活高效的 CAD 软件进行设计起着至关重要的作用。

Established in 2008, 2elle-engineering Srl is a globally renowned manufacturer of one-piece and modular forged wheels located close to Padua, Italy. Despite challenges within the automotive sector and the recent pandemic, the company has consistently achieved remarkable growth in both revenue and workforce, and now boasts over 70 employees.

2elle-engineering Srl 成立于 2008 年,是一家全球知名的一体式和模块化锻造轮毂制造商,位于意大利帕多瓦附近。尽管汽车行业面临挑战和最近的大流行,但该公司在收入和员工人数方面一直取得了显着增长,目前拥有 70 多名员工。

2elle工程团队:左起:Davide Lucaora、Leonardo Righi、Christian Coletto和Riccardo Cutrino

Brothers Davide and Alessandro Lucaora share responsibility for the technical-production and the financial-commercial sides of the family business.

Davide 和 Alessandro Lucaora 兄弟共同负责家族企业的技术生产和金融商业方面。

“We collaborate with renowned competition teams, major tuner brands, international military and security vehicle manufacturers, and of course the world’s top car manufacturers,” notes Davide Lucaora when describing their customer base. The exceptional quality and reliability of wheels from 2elle-engineering have even earned them the coveted DUNS number from the Volkswagen Group, a certification reserved for the most esteemed suppliers.

“我们与著名的比赛团队、主要改装品牌、国际军事和安全汽车制造商合作,当然还有世界顶级汽车制造商,”Davide Lucaora 在描述他们的客户群时指出。2elle-engineering 车轮的卓越品质和可靠性甚至为他们赢得了大众汽车集团令人垂涎的 DUNS 编号,这是为最受尊敬的供应商保留的认证。

Forged Wheels: Elevating Performance and Elegance

锻造轮毂:提升性能和优雅

The heart of 2elle-engineering’s ingenuity lies in careful crafting of hot forged aluminum for their one-piece and modular wheel rims. Unlike traditional aluminum diecast wheels, forged wheels are engineered from aluminum alloy billets that are heated above the recrystallization temperature into a plastic condition. The billets are then transformed through repeated hammer blows or presses, resulting in a product of exceptional strength and resilience.

2elle-engineering独创性的核心在于精心制作热锻铝,用于其一体式和模块化轮辋。与传统的铝压铸轮毂不同,锻造轮毂由铝合金坯料制成,这些坯料被加热到再结晶温度以上,形成塑性状态。然后通过反复锤击或压力机将坯料转化为具有非凡强度和弹性的产品。

2elle-engineering Srl 制造的锻造轮毂被广泛认为是顶级产品,标志着对质量的绝对关注。

Forged wheels possess a finer grain structure, leading to greater mechanical strength and durability, and a more effective stress distribution over a larger surface area. As a result, these premium wheels outperform their diecast counterparts in performance, safety, and ride comfort. Producing a range of forged rims from 13 to 24 inches, the high-end vehicle market seeks out 2elle-engineering’s forged wheels, valuing the relentless craftsmanship that embodies both premium aesthetics and rugged functionality.

锻造车轮具有更细的晶粒结构,从而具有更高的机械强度和耐用性,并在更大的表面积上更有效地分布应力。因此,这些优质车轮在性能、安全性和乘坐舒适性方面优于压铸车轮。生产从 13 英寸到 24 英寸的一系列锻造轮辋,高端汽车市场寻求 2elle-engineering 的锻造轮毂,重视体现优质美学和坚固功能的不懈工艺。

Highest Quality with the Fastest Process

以最快的工艺实现最高质量

2elle-engineering strives for absolute quality in the shortest possible time by focusing on meticulous inspection at every step of production, from CAD design and structural analysis, to machining the forged blank, through to special finishes or painting. The workshop operates 24 hours a day to ensure prompt order fulfillment. The technical department is equally agile, capable of producing wheel designs within 24 hours, regardless of how the request is made – be it through 3D models, images, or sketches.

2elle-engineering致力于在最短的时间内实现绝对的质量,从CAD设计和结构分析,到锻造毛坯的加工,再到特殊表面处理或喷漆,在生产的每一步都进行细致的检查。车间全天24小时运作,确保及时完成订单。技术部门同样敏捷,能够在 24 小时内完成车轮设计,无论请求是如何提出的——无论是通过 3D 模型、图像还是草图。

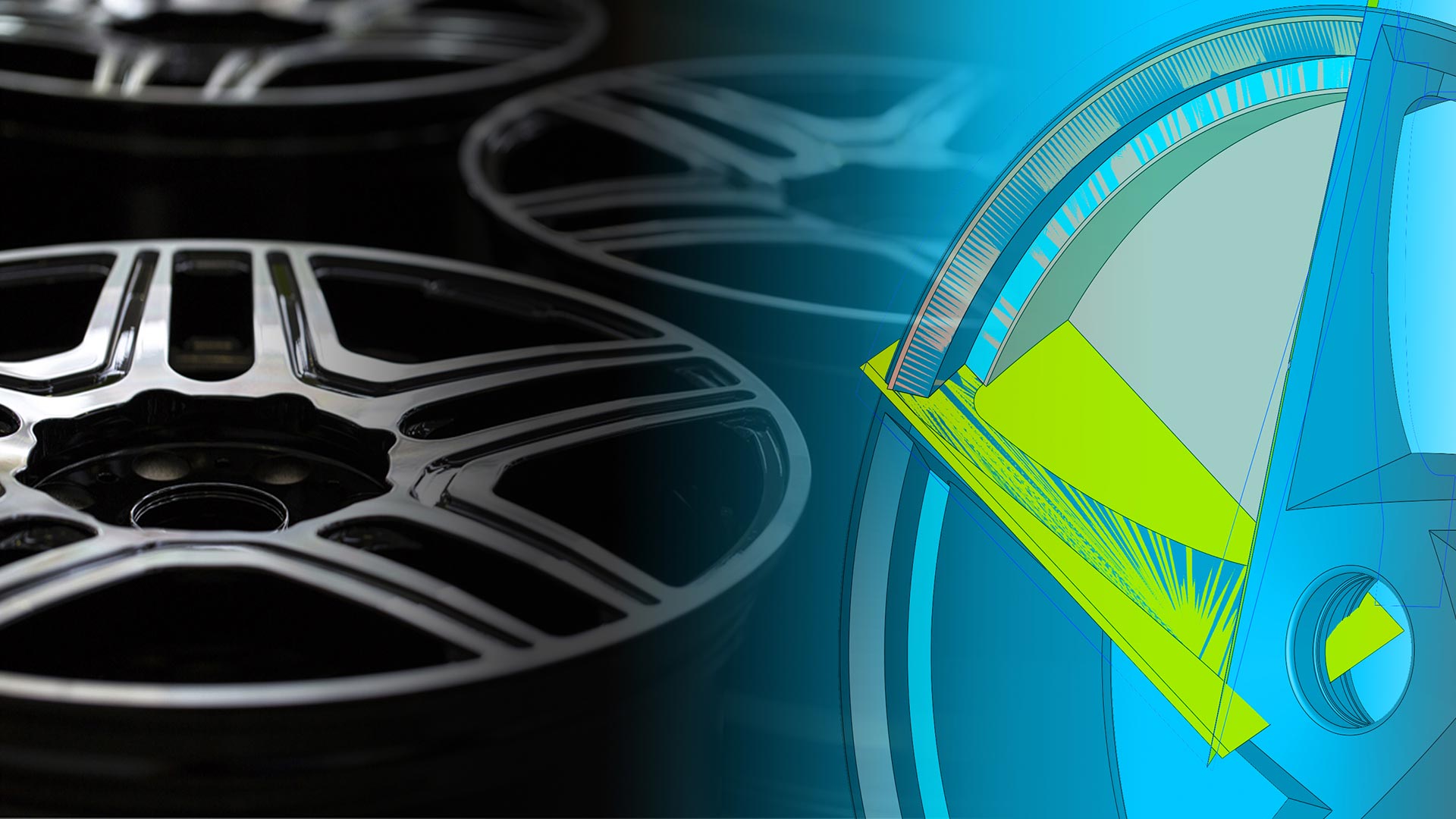

CAD Software that Empowers Flexibility and Collaboration

支持灵活性和协作的 CAD 软件

For the designers at 2elle-engineering, Cimatron offers a seamless integration of design and manufacturing processes that enable a rapid response to customer requirements. The immediacy of the software helps to accelerate the process and enables a more effective collaboration workflow. Lucaora explains, “The stylists are creative and sometimes in their designs they forget that inside the rim there must also be a place for the mechanics of the car, such as brake calipers. The aesthetic elements must be checked by us to allow the necessary clearances and avoid potential interference. We then must verify all overall dimensions and simulate the structural loads. For some armored vehicles, each wheel must be capable of bearing multiple tons of weight. Thanks to Cimatron’s capabilities, we can easily extract the internal geometry, set suitable thicknesses, instantly change profiles, and try other solutions. Generally, once the design is set up, most of the work is already done because the changes are quick to implement.”

对于2elle-engineering的设计师来说,Cimatron提供了设计和制造流程的无缝集成,能够快速响应客户的要求。该软件的即时性有助于加快流程并实现更有效的协作工作流程。Lucaora解释说:“造型师很有创意,有时在设计中他们忘记了轮辋内部也必须有一个位置来放置汽车的机械装置,例如制动卡钳。我们必须检查美学元素,以允许必要的间隙并避免潜在的干扰。然后,我们必须验证所有整体尺寸并模拟结构荷载。对于某些装甲车,每个车轮必须能够承受数吨的重量。借助 Cimatron 的能力,我们可以轻松提取内部几何形状、设置合适的厚度、立即更改轮廓并尝试其他解决方案。一般来说,一旦设计设置好,大部分工作就已经完成,因为更改可以快速实施。

Sketching is another function of Cimatron employed by the 2elle-engineering technical department. “It serves as an environment that provides valuable guidelines for the design concept. We can define lines, extrude shapes, model various surfaces, add dimensions, constraints and parametric relationships. It is convenient to be able to set the axis at different points and use the various planes to create new geometry. The user experience is simpler, automation increases, and the design is completed in less time. For example, the system automatically recognizes the center of a hole without the operator having to add it manually.” Lucaora remarks, “ We work on the project, and Cimatron equips us with the necessary tools to develop the design, which will eventually be sent to the foundry for the production of the blank.”

草图绘制是 Cimatron 的另一项功能,由 2elle 工程技术部门使用。“它作为一个环境,为设计概念提供了有价值的指导。我们可以定义线条、拉伸形状、对各种曲面进行建模、添加尺寸、约束和参数关系。能够在不同的点设置轴并使用各种平面来创建新的几何形状是很方便的。用户体验更简单,自动化程度提高,设计在更短的时间内完成。例如,系统可以自动识别孔的中心,而无需操作员手动添加孔。Lucaora评论说:“我们参与了这个项目,Cimatron为我们提供了开发设计的必要工具,这些工具最终将被送往铸造厂生产毛坯。

Cimatron 模板允许按照 2elle 工程标准一致地进行设计。

We work on the project, and Cimatron equips us with the necessary tools to develop the design, which will eventually be sent to the foundry for the production of the blank.

我们参与该项目,Cimatron为我们提供了开发设计的必要工具,最终将发送到铸造厂生产毛坯。

Davide Lucaora,2elle-engineering Srl 技术/生产经理

Automating Designs and Capturing Business Knowledge

自动化设计并获取业务知识

Cimatron’s hybrid modeling functions also play a vital role in streamlining the design process for 2elle-engineering. “Summary tables are particularly useful to us because they are obtained automatically from the three-dimensional model,” claims Lucaora. “By doing so, we avoid the risk of making mistakes due to unnecessary repetition or misunderstanding data. The tables can include sections, bills of material, bore tables, the information needed to order components, as well as perform machining in the workshop, and manage quality and documentation.” Their use of summary tables helps to automate and standardize the design process by allowing the use of previously saved procedures that were customized with company knowledge, experience and expert ‘know-how’. These standards and procedures can be passed on immediately for operators to use on future projects.

Cimatron 的混合建模功能在简化 2elle-engineering 的设计流程方面也发挥着至关重要的作用。“汇总表对我们特别有用,因为它们是从三维模型中自动获取的,”Lucaora 说。“通过这样做,我们避免了因不必要的重复或误解数据而出错的风险。这些表格可以包括截面、物料清单、孔表、订购组件所需的信息,以及在车间进行加工,以及管理质量和文档。他们使用汇总表,允许使用以前保存的程序,这些程序是根据公司知识、经验和专家“诀窍”定制的,有助于设计过程的自动化和标准化。这些标准和程序可以立即传递,供运营商在未来的项目中使用。

Cimatron 使设计人员能够设置各种参数,以精确控制设计过程的每个步骤。

Future perspectives 未来展望

2elle-engineering’s relentless pursuit of excellence extends beyond their current success. Lucaora remarks, “Market demands have convinced us that we can double our production capacity and indeed the expansion continues.” Recent investments in a state-of-the-art automatic painting department have significantly shortened the production chain, slashing turnaround times and elevating overall operational efficiency. The company now sets its sights on pioneering new projects, notably carbon-fiber wheels featuring an aluminum central flange with a carbon channel. Lucaora observes, “Carbon fiber guarantees a more comfortable ride for the car because it does not induce vibrations, it does not ‘sound’ like a metal wheel would. This innovation has already been adopted, for example, on some Rolls Royce models. Of course, it’s the same niche, high-tech market in which we excel.”

2elle-engineering对卓越的不懈追求超越了他们目前的成功。Lucaora表示:“市场需求让我们相信,我们可以将产能提高一倍,而且扩张仍在继续。最近对最先进的自动涂装部门的投资大大缩短了生产链,缩短了周转时间,提高了整体运营效率。该公司现在将目光投向了开创性的新项目,特别是碳纤维轮毂,该轮毂具有带碳通道的铝制中央法兰。Lucaora说:“碳纤维保证了汽车更舒适的乘坐体验,因为它不会引起振动,也不会像金属车轮那样'发出'声音。例如,这项创新已经在一些劳斯莱斯车型上被采用。当然,这是我们擅长的利基高科技市场。