BNL Bearings BNL轴承

Bearing It All 承受一切

How BNL Bearings have used CADCAM to turn products around faster

BNL Bearings 如何使用 CADCAM 更快地完成产品周转

Bearings make the world go round - almost literally. These essential mechanical elements are a key ingredient in making sure that objects move the right way, with anything that turns requiring one.

轴承让世界运转起来——几乎是字面意思。这些基本的机械元件是确保物体以正确方式移动的关键因素,任何转动都需要一个。

As a result, they’re used in many of the major industries, from automotive to food processing, and have hundreds of thousands of other applications. Without bearings, and the motion that they allow, the world would come to a stand still.

因此,它们被用于许多主要行业,从汽车到食品加工,并有数十万种其他应用。没有方位,没有它们允许的运动,世界就会停滞不前。

The world leader in producing integrated plastic bearings, BNL Bearings has been at the forefront of designing and manufacturing these rolling element bearings since the company’s founding in 1970. Since then, their processes have been refined and perfected, despite becoming more complex, in order to allow them to produce bearings for an ever-increasing number of global markets and adapt to a constantly changing world.

BNL轴承是生产集成塑料轴承的全球领导者,自1970年成立以来,BNL轴承一直处于设计和制造这些滚动轴承的最前沿。从那时起,尽管变得越来越复杂,但他们的工艺得到了改进和完善,以便能够为越来越多的全球市场生产轴承,并适应不断变化的世界。

Picking Plastic 拣选塑料

However, with most bearings being made out of metal, BNL’s dedication to making plastic ones begs the question: why would a plastic bearing be preferable?

然而,由于大多数轴承都是由金属制成的,BNL致力于制造塑料轴承,这引出了一个问题:为什么塑料轴承更可取?

The answers are manyfold, a key one being that plastic bearings don’t corrode. Naturally, many metals are susceptible to corrosion from water and chemicals, which leads to the premature wear of the bearing, so the bearing and the product it is used in will have a reduced operational life.

答案是多方面的,其中一个关键是塑料轴承不会腐蚀。当然,许多金属容易受到水和化学品的腐蚀,导致轴承过早磨损,因此轴承及其使用的产品将缩短使用寿命。

As a result, BNL’s plastic non-corrosive bearings are common in industries where water is heavily present, such as shower doors or pool cleaners. Similarly, products that are built for outdoor use will need non-corrosive bearings, because they will be exposed to the elements. For example, plastic bearings used in a wind turbine will be protected from the elements, while bearings used in applications such as yacht and boat rigging will be protected from wear caused by salt water.

因此,BNL的塑料非腐蚀性轴承在大量含水的行业中很常见,例如淋浴门或泳池清洁器。同样,为户外使用而制造的产品将需要非腐蚀性轴承,因为它们会暴露在元素中。例如,风力涡轮机中使用的塑料轴承将受到保护,免受元素的影响,而用于游艇和船只索具等应用的轴承将受到保护,免受盐水造成的磨损。

BNL’s plastic bearings also boast chemical-resistance, which is particularly helpful when the bearings are used in certain environments. The BNL bearings that are made out of specialist materials, such as UHMWPE and PEEK, are put to use in hostile habitats such as the chemical baths used in LED screen processing, an environment that would cause many metal bearings to fail prematurely. Additionally, chemical-resistant plastic bearings are invaluable in the food industry, where avoiding contamination is vital. Disinfecting the conveyor systems is crucial, so it’s important that the bearings used in the wheels aren’t worn by the chemical disinfectants from the frequent washdowns.

BNL的塑料轴承还具有耐化学性,这在轴承在某些环境中使用时特别有用。由UHMWPE和PEEK等专业材料制成的BNL轴承被用于恶劣的环境,例如LED屏幕加工中使用的化学浴,这种环境会导致许多金属轴承过早失效。此外,耐化学腐蚀的塑料轴承在食品工业中是无价的,因为在食品工业中,避免污染至关重要。对输送系统进行消毒至关重要,因此重要的是,车轮中使用的轴承不会因频繁冲洗而被化学消毒剂磨损。

Another reason for opting for plastic bearings over metal ones is the fact that they don’t require lubricant. “Thermoplastics are inherently lubricated, so BNL bearings do not need to be greased,” says BNL’s UK Tooling Manager Dave Clark, a benefit which makes maintenance far easier.

选择塑料轴承而不是金属轴承的另一个原因是它们不需要润滑剂。“热塑性塑料本身就具有润滑作用,因此BNL轴承不需要润滑,”BNL的英国模具经理Dave Clark说,这一优势使维护变得更加容易。

This is particularly useful in the paper path industries, where lubrication could otherwise ruin the paper. Whether it’s an ATM depositing cash or a printer generating hard copies, lubricant can cause the paper to be blemished with unwanted markings, ruining banknotes or hard copies. The issues don’t end there, either, when it comes to printers and photocopiers, because the toner can mix with the lubricant, which creates a grinding paste that then wears the bearing prematurely. With a BNL bearing, these problems can be avoided.

这在造纸路径行业特别有用,否则润滑可能会损坏纸张。无论是存入现金的 ATM 机还是生成硬拷贝的打印机,润滑剂都会导致纸张上出现不必要的标记、损坏钞票或硬拷贝。当涉及到打印机和复印机时,问题也不止于此,因为碳粉会与润滑剂混合,从而形成研磨膏,然后过早磨损轴承。使用BNL轴承,可以避免这些问题。

Evidently, plastic bearings that are free of lubrication help to make their products easier and more cost-effective to maintain. It’s a notable benefit and one that, in fact, gave BNL its name - the acronym stands for Bearings Non-Lube. Plastic’s inherent lightness can also contribute to energy efficiencies. BNL’s plastic bearing designs are generally much lighter than a steel equivalent, but using their trademark integrated design techniques to remove components and fixings from the product, custom designed bearings can be up to 50% lighter than an alternative multi-component solution. In reducing weight, they reduce torque to rotate on start-up and in operation, which means that smaller, less expensive motors can be used. Meanwhile, using lighter weight bearings in vehicle steering columns helps to lower the vehicle’s overall weight, helping contribute to a reduction in its carbon emissions.

显然,无需润滑的塑料轴承有助于使其产品更易于维护且更具成本效益。这是一个显着的好处,事实上,BNL 也因此而得名——首字母缩写词代表轴承非润滑。塑料固有的轻盈性也有助于提高能源效率。BNL 的塑料轴承设计通常比钢轴承轻得多,但使用其标志性的集成设计技术从产品中去除组件和固定件,定制设计的轴承可以比替代的多组件解决方案轻 50%。在减轻重量的同时,它们降低了启动和运行时旋转的扭矩,这意味着可以使用更小、更便宜的电机。同时,在车辆转向柱中使用重量更轻的轴承有助于降低车辆的整体重量,有助于减少碳排放。

As if all that wasn’t enough, BNL’s plastic bearings can offer plenty of financial benefit too. For one thing, plastic materials can be less costly than a metal equivalent like steel. On top of that, the fact that BNL can design and mould their bearings allows them to combine mating parts into one product, reducing component count for their customers’ products. With fewer components, there are fewer costs, as well as reduced assembly steps and time. As for their application, the lighter and more energy efficient bearings mean that the products they’re used in can be more compact, and this helps save money on inventory costs and logistics too.

似乎这些还不够,BNL的塑料轴承也可以提供大量的经济效益。首先,塑料材料可能比钢等金属等金属材料成本更低。最重要的是,BNL可以设计和模制他们的轴承,使他们能够将配合部件组合成一个产品,从而减少客户产品的组件数量。组件更少,成本更低,组装步骤和时间也更少。至于它们的应用,更轻、更节能的轴承意味着它们所使用的产品可以更紧凑,这也有助于节省库存成本和物流成本。

As you can see, BNL’s primary selling point of moulding their plastic bearings - a form of comprehensive control that allows for improved performance, whole system cost reductions, simplified maintenance, and much more - is incredibly beneficial. But what are BNL’s moulding techniques?

正如你所看到的,BNL的主要卖点是模制他们的塑料轴承--一种全面的控制形式,可以提高性能、降低整个系统成本、简化维护等等--是非常有益的。但是BNL的成型技术是什么?

Moulding For Precision 精密成型

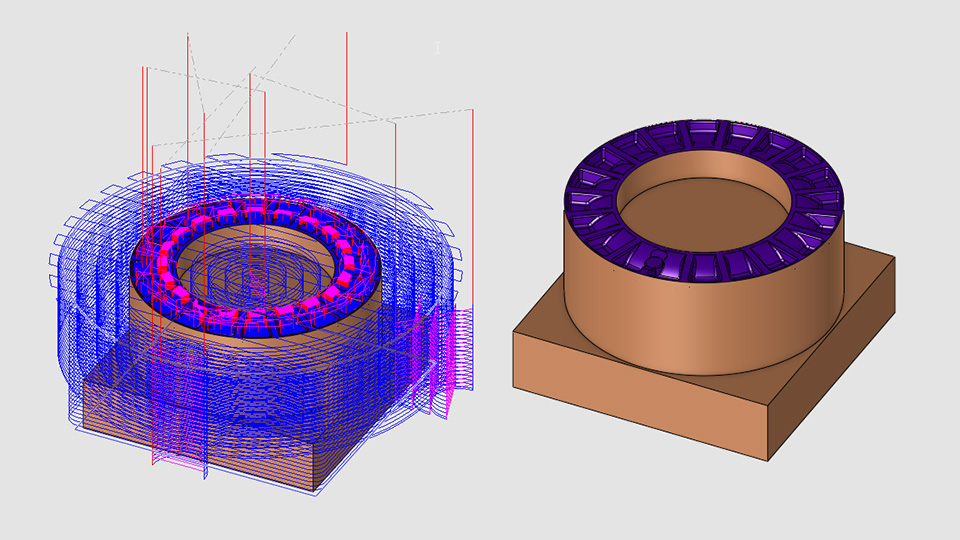

Injection moulding is the technique of choice for BNL - and one that they’ve perfected for bearing manufacture. “About 99%” of their products are injection moulded, says Clark, with the 1% that aren’t simply being such low volume that they don’t justify the tools.

注塑成型是BNL的首选技术,也是他们在轴承制造中完善的技术。克拉克说,他们“大约99%”的产品是注塑成型的,其中1%的产品不仅仅是产量太低,以至于他们没有理由使用这些工具。

The injection moulding process involves molten plastic being squeezed into a mould at high pressure, before water cools it and the plastic solidifies. It’s a process that allows for extremely high precision products to be made, which is crucial when dealing with bearings since they can come in all sizes. For example, an extremely small bearing will need to be intricately designed in order for it to work properly.

注塑成型过程包括将熔融塑料在高压下挤压到模具中,然后水冷却并塑料凝固。这是一个可以制造极高精度产品的过程,这在处理轴承时至关重要,因为它们可以有各种尺寸。例如,一个非常小的轴承需要经过复杂的设计才能正常工作。

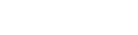

However, before the injection moulding process can begin, a design for the product and the mould needs to be created - which is where Cimatron software comes into play.

然而,在注塑成型过程开始之前,需要为产品和模具创建设计 - 这就是 Cimatron 软件发挥作用的地方。

In-House Tool Design 内部工具设计

BNL has found immense success with Cimatron CADCAM software since first embracing it in 2006, and that shows no signs of changing. “Previously to BNL doing its own in-house designs,” says Clark, “it used to purchase all its tool designs externally.”

自 2006 年首次采用 Cimatron CADCAM 软件以来,BNL 在 Cimatron CADCAM 软件方面取得了巨大的成功,而且没有改变的迹象。Clark 说:“以前 BNL 自己进行内部设计,过去它的所有工具设计都是从外部购买的。

Though this was an ample way of operating, they found that relying on a toolmaker’s tool design had its shortcomings, because the toolmakers were simply less familiar with the processes and precision needed to manufacture moulded plastic bearings than BNL. Naturally, when the moulding process requires as many features and as much precision as injection moulding, familiarity is vital.

尽管这是一种充足的操作方式,但他们发现依赖工具制造商的模具设计有其缺点,因为工具制造商对制造模制塑料轴承所需的工艺和精度的熟悉程度不如BNL。当然,当成型过程需要与注塑成型一样多的特征和精度时,熟悉度至关重要。

Additionally, Clark notes that “we got better control of the tool design by doing our own in-house tool designs”. Control is important, allowing BNL to get exactly the dimensional development they want, and “we do all the programming in Cimatron.” From adjusting the tool design, which is done with the Mold Design package, to even the 3D CAM package that’s used for transferring to the machines on the shop floor, Cimatron provides an intuitive, efficient way to work.

此外,Clark 指出,“通过进行自己的内部工具设计,我们可以更好地控制工具设计”。控制很重要,它使BNL能够准确地获得他们想要的维度开发,“我们在Cimatron中完成所有编程。从调整模具设计(使用模具设计软件包完成)到用于转移到车间机器的 3D CAM 软件包,Cimatron 提供了一种直观、高效的工作方式。

We found that the Cimatron package targeted plastic pack design and plastic tool design in a way that gave the company a much easier, much quicker process than other packages at that time.

我们发现,Cimatron的包装以塑料包装设计和塑料工具设计为目标,与当时的其他包装相比,它为公司提供了更简单、更快捷的流程。

Dave Clark,BNL 工具经理

Selecting Cimatron over other CADCAM softwares was the result of reviewing a number of different ones, as well as a recommendation from one of BNL’s toolmakers. Says Clark, “we found that the Cimatron package targeted that plastic pack design and plastic tool design” in a way that gave the company a much easier, much quicker process than other packages at that time.

选择Cimatron而不是其他CADCAM软件,是审查了许多不同的软件的结果,也是BNL工具制造商之一的建议。Clark 说,“我们发现 Cimatron 封装针对的是塑料包装设计和塑料工具设计”,与当时的其他包装相比,它为公司提供了更简单、更快捷的流程。

But does it still hold up after all these years? The answer is a resounding yes. BNL regularly talks to other sub-contract designers who also use Cimatron, and the consensus is that it still provides a far quicker way of doing things.

但这么多年过去了,它还能站得住脚吗?答案是肯定的。BNL定期与其他也使用Cimatron的分包设计师交谈,大家的共识是,它仍然提供了一种更快的做事方式。

The Future 未来

BNL’s plastic bearings are essential to an enormous range of industries. From conveyor systems to conference cameras, and even smart controls to dishwashers, BNL’s print can be found everywhere and their reach will only expand.

BNL的塑料轴承对各行各业至关重要。从传送带系统到会议摄像机,甚至智能控制到洗碗机,BNL的印刷品随处可见,而且其覆盖范围只会扩大。

One of the primary industries is the automotive world, where bearings are crucial to many parts of a vehicle, such as steering columns and infotainment control. However, with so many vehicles now moving to LCD touchscreens, you might imagine that there will be less of a need for knobs and their bearings - not so.

汽车领域是主要行业之一,轴承对车辆的许多部件至关重要,例如转向柱和信息娱乐控制。然而,随着现在有如此多的车辆转向 LCD 触摸屏,您可能会认为对旋钮及其轴承的需求会减少——事实并非如此。

“Market research by the big OEMs have shown that drivers don’t like the fact that you have to take your eyes off the road to operate the screen, and there are recognised safety concerns in the industry,” says Clark. “Drivers still prefer the knobs and switch-type situation.” This is where one of BNL’s recent innovative ventures arises.

克拉克说:“大型原始设备制造商的市场研究表明,驾驶员不喜欢必须将视线从道路上移开才能操作屏幕的事实,而且业内存在公认的安全问题。“驾驶员仍然更喜欢旋钮和开关类型的情况。”这就是BNL最近的一项创新企业的诞生地。

Working closely with leading corporation Microchip Technology Inc., BNL has designed “a control knob that can be positioned and fixed to a capacitive screen, where it then allows the driver to operate the screen menus and selections via turning and pressing the BNL control. Rather than needing to swipe and touch specific areas of the screen, which would require the driver to look away from the road, the BNL control knob rotates through the menu options and provides haptic feedback to the driver, who can then select their option with a push.”

BNL与领先的Microchip Technology Inc.密切合作,设计了“一个控制旋钮,可以定位并固定在电容式屏幕上,然后允许驾驶员通过转动和按下BNL控制来操作屏幕菜单和选择。BNL控制旋钮无需滑动和触摸屏幕的特定区域,这需要驾驶员将视线从道路上移开,而是在菜单选项之间旋转,并向驾驶员提供触觉反馈,然后驾驶员可以通过按下来选择他们的选项。

Known as “Knob-on-Display”, BNL’s design proves the desire for rotational function will continue but that bearing designs will need to adapt with the advancements of more digital technologies - and BNL’s integrated custom bearing designs are already advancing towards this future.

BNL的设计被称为“Knob-on-Display”,证明了对旋转功能的渴望将继续下去,但轴承设计需要适应更多数字技术的进步 - BNL的集成定制轴承设计已经朝着这个未来迈进。

It’s an innovative concept from a company rife with new ideas, and one that is able to be brought to life with Cimatron software and a team of highly skilled engineers.

这是一个来自充满新想法的公司的创新概念,并且能够通过Cimatron软件和高技能工程师团队实现。

Written by Rupert Morgans-Wicks, CDG 3D TECH

作者RupertMorgans-Wicks,CDG3DTECH