ALPLA - 通过机器上的质量测量实现稳定的生产过程

Alpla Group 阿尔普拉集团

High precision measurements from Cimatron creates a stronger process

Cimatron 的高精度测量创造了一个更强大的过程

For us, it is particularly important that the software experts at Cimatron always listen to our wishes, suggestions and needs. They listen to us very carefully and also implement the suggestions promptly. This way, we get practical solutions for our challenges very quickly

对我们来说,Cimatron的软件专家始终倾听我们的愿望、建议和需求尤为重要。他们非常认真地听取我们的意见,并及时实施建议。通过这种方式,我们可以非常快速地获得应对挑战的实用解决方案

Tim Helbock,Alpla Toolmaking 开发人员

At the family-run Alpla Group in Hard, Vorarlberg, high-quality packaging systems are one of the products manufactured. In theold shop at the group’s mai site, the toolmakers primarily build blow molds for PET bottles and injection molds for the screw caps that go with them. For the necessary data consistency and a high level of process stability and safety, the experts in injection mold making rely on the Cimatron CAD/CAM system.

在位于福拉尔贝格州哈德的家族企业Alpla Group,高质量的包装系统是生产的产品之一。在集团麦工厂的老车间里,工具制造商主要为PET瓶制造吹塑模具,并为与之配套的螺旋盖制造注塑模具。为了获得必要的数据一致性和高水平的过程稳定性和安全性,注塑模具制造专家依靠Cimatron CAD/CAM系统。

The Alpla Group’s headquarters in Hard in Vorarlberg, Austria, is also home to the company’s lead moldmaking facility. The mold makers primarily produce blow molds for PET bottles and high-cavity injection molds for the caps of these bottles, but also caps for other food packaging or even cosmetics. High precision and, in particular, accurate repeatability, especially in the production of the cavities of the complex injection molds, characterize the work of the moldmakers.

Alpla 集团总部位于奥地利福拉尔贝格州的哈德,也是该公司铅模制造工厂的所在地。模具制造商主要生产用于PET瓶的吹塑模具和用于这些瓶盖的高腔注塑模具,但也生产用于其他食品包装甚至化妆品的瓶盖。高精度,特别是精确的可重复性,特别是在复杂注塑模具的型腔生产中,是模具制造商工作的特点。

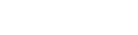

Cimatron 为 Alpla 工具车间的自动化提供必要的数据。这些电极由 Kuka 机器人在 Hermle 铣削单元中制造,该铣削单元包括两台 Hermle C 42 U 和一台高精度 Röders RXP 950 DSH HSC 铣床。- 图片:Pergler Media

“Our mold shop has a very high level of automation,” explains Tim Helbock, developer at Alpla. “Among other things, we operate a fully automated EDM line that includes four die-sinking EDM machines as well as coordinate measuring machines from Zeiss and a MAFAC washing machine on an Erowa automation system. A Hermle automation system houses two Hermle C 42 U universal machining centers for machining unhardened steels and a Röders RXP 950 DSH HSC milling machine for electrode and hard milling.”

“我们的模具车间具有非常高的自动化水平,”Alpla 开发人员 Tim Helbock 解释道。“除此之外,我们还运营着一条全自动电火花加工生产线,其中包括四台电火花成形加工机、蔡司的三坐标测量机和一台基于 Erowa 自动化系统的 MAFAC 清洗机。Hermle 自动化系统包含两台用于加工未淬硬钢的 Hermle C 42 U 万能加工中心和一台用于电极和硬铣削的 Röders RXP 950 DSH HSC 铣床。

Both lines operate fully automatically and Cimatron supplies the programs and important data for communication with the CERTA job management system of the Erowa line and the Soflex system of the milling cell. The Zoller TMS tool management system also exchanges its data with Cimatron in real time. The excellent interfaces of the CAD/CAM package ensure high data consistency. In addition, Cimatron supplies data for exchange with the Plantool ERP system, which enables transparent and up-to-date production planning in the production control system. The toolmaking know-how at Alpla came into the company about ten years ago with the takeover of the external M+S toolmaking company, which was also located in Hard and with which Alpla had already had a long-standing partnership.

两条生产线都全自动运行,Cimatron 提供程序和重要数据,以便与 Erowa 生产线的 CERTA 作业管理系统和铣刨单元的 Soflex 系统进行通信。Zoller TMS 刀具管理系统还与 Cimatron 实时交换数据。CAD/CAM软件包的出色接口确保了高度的数据一致性。此外,Cimatron 还提供数据,以便与 Plantool ERP 系统进行交换,从而在生产控制系统中实现透明和最新的生产计划。大约十年前,Alpla 收购了外部 M+S 模具制造公司,该公司也位于 Hard,并且已经与该公司建立了长期合作伙伴关系,从而将 Alpla 的模具制造技术带入了公司。

The new department, which has since grown to 50 employees, started with the six employees of this tool shop. From the very beginning, the goal was to make appropriate use of the digital possibilities of Industry 4.0 wherever it makes sense to do so. This requires powerful software as the backbone of production. The people in charge made a very conscious decision in favor of Cimatron here.

新部门现已发展到 50 名员工,从这家工具车间的 6 名员工开始。从一开始,我们的目标就是在有意义的地方适当利用工业 4.0 的数字化可能性。这需要强大的软件作为生产的支柱。负责人在这里做出了一个非常有意识的决定,支持Cimatron。

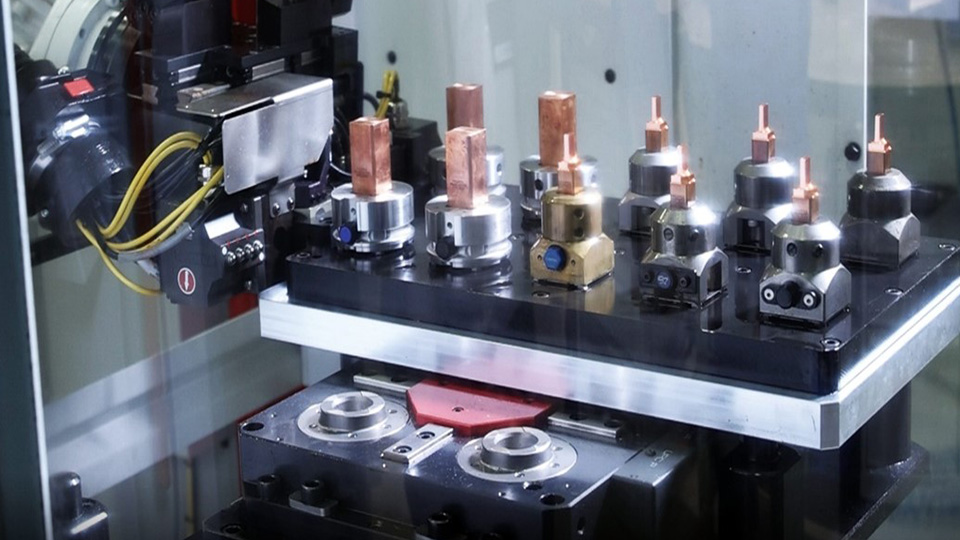

机器人夹持器将电极坯料定位在 Röders RXP 950 DSH HSC 铣床的工作区域。Cimatron 和 Soflex 相互作用,以确保机床加载适当的铣削程序并开始加工。- 图片:Pergler Media

The entry into Cimatron was once made via the CAD functions, which exactly fit the needs of the new internal tool and die shop. Today, however, the CAM side is at least as important - thanks to the high level of expertise of Cimatron’s post-processing specialists, the programs are very accurate and the simulation of machining also matches reality exactly. The software package is the data backbone that provides all machines with valid and up-to-date information.

Cimatron的进入曾经是通过CAD功能完成的,这完全符合新的内部工具和模具车间的需求。然而,今天,CAM方面至少同样重要 - 由于Cimatron后处理专家的高水平专业知识,程序非常准确,加工模拟也完全符合现实。软件包是数据主干,为所有机器提供有效和最新的信息。

The system plays to its strengths at Alpla, particularly in the area of electrodes, assemblies and support. “What is always fascinating for us is how much the Cimatron specialists know about machines - they are downright freaks in the best sense,” Helbock reveals. “They test the limits of the machines and in doing so ensure efficient, productive processes that are also stable and safe.”

该系统在Alpla发挥其优势,特别是在电极、组件和支撑领域。“对我们来说,最吸引人的是 Cimatron 专家对机器的了解程度——从最好的意义上说,他们是彻头彻尾的怪胎,”Helbock 透露。“他们测试机器的极限,从而确保高效、高产的流程,同时保持稳定和安全。”

在加工之前,Cimatron 将铣削程序与所有相关数据进行比较,并检查它们是否存在碰撞。除其他外,数字孪生还与 Zoller 工具管理中的工具的真实数据一起工作。- 图片:Pergler Media

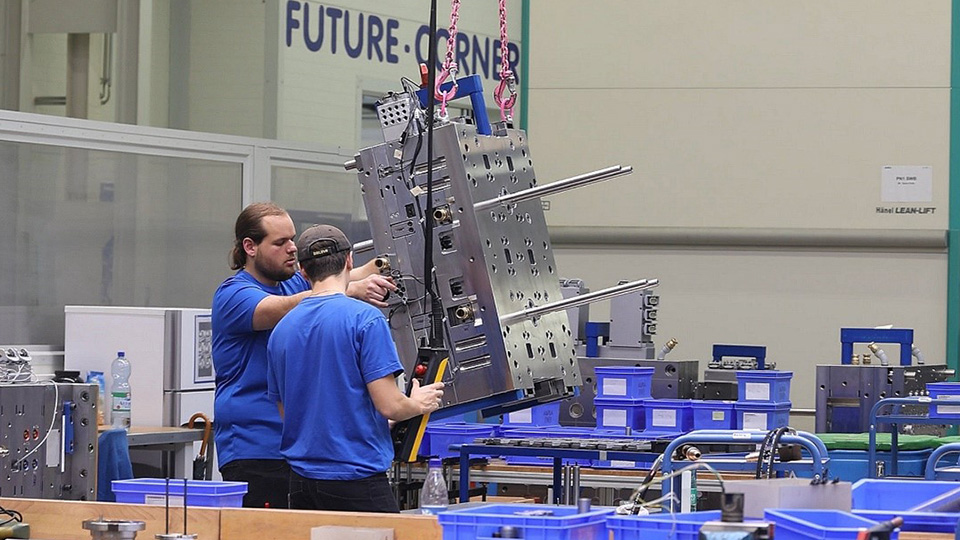

At Alpla, the tool specialists erode with both graphite and copper electrodes. “For 3D geometries, graphite electrodes are the better choice for us,” explains Helbock. “For mold sections with sealing surfaces, however, we still rely on copper electrodes - this enables perfectly sealing surfaces.” The copper electrodes are primarily created on the Röders RXP 950 DSH HSC milling machine.

在Alpla,刀具专家使用石墨和铜电极进行电火花加工。“对于 3D 几何形状,石墨电极是我们更好的选择,”Helbock 解释道。“然而,对于具有密封表面的模具部分,我们仍然依赖铜电极 - 这样可以完美地密封表面。”铜电极主要在 Röders RXP 950 DSH HSC 铣床上制造。

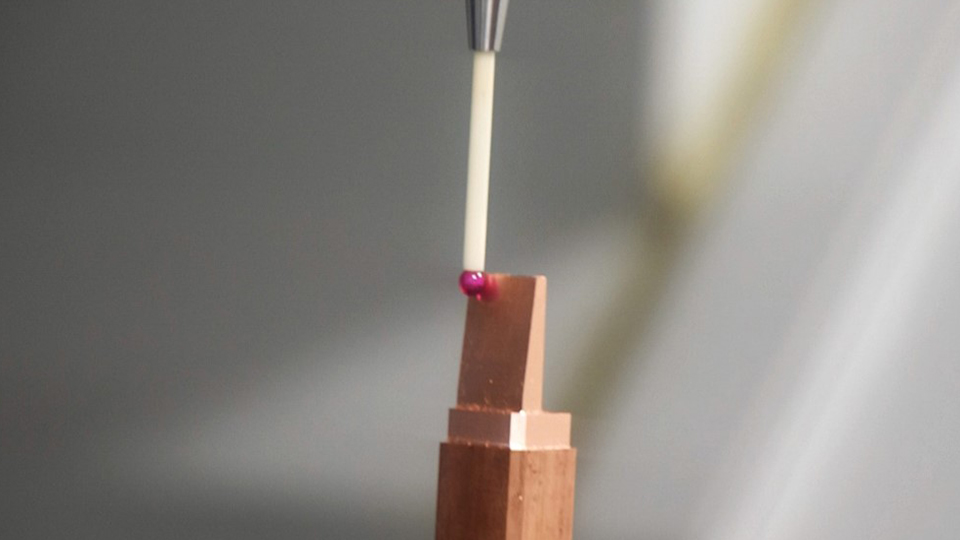

The tolerances here are in the lower single-digit μm range. And to ensure that deviations from the nominal dimension cannot affect subsequent operations, it would be a great advantage for the toolmakers to measure the milled electrodes while they are still being clamped in the automation line. This would allow corrections to be made quickly and precisely.

此处的公差在较低的个位数μm范围内。为了确保与标称尺寸的偏差不会影响后续操作,对于工具制造商来说,在铣削电极仍被夹在自动化生产线中时对其进行测量将是一个很大的优势。这样可以快速准确地进行更正。

黑色或红色 - 预期用途决定:模具制造商喜欢将石墨电极用于复杂的 3D 几何形状。但是,例如,当涉及到密封表面时,模具专家仍然对铜电极发誓。- 图片:Pergler Media

“However, we do not have a coordinate measuring machine integrated in our milling line,” Helbock emphasizes. “So for measuring, we would first have to bring the electrode to the measuring machine in the EDM line or in the measuring room, measure it there and then transfer it back to the milling line for any necessary correction. Manual steps that cost time and would severely disrupt the otherwise highly automated process in our production.”

“然而,我们的铣削生产线中没有集成三坐标测量机,”Helbock 强调说。“因此,在进行测量时,我们首先必须将电极带到电火花线或测量室的测量机上,在那里进行测量,然后将其转移回铣削线进行必要的校正。手动步骤会耗费时间,并且会严重破坏我们生产中原本高度自动化的流程。

The alternative came in the form of the new Röders RXP 950 DSH HSC milling machine integrated into the milling cell: “This machine brings the high level of accuracy required, which allows full-fledged quality measurement on the machine,” explains Helbock. “Cimatron generates the measuring points relevant for this from the workpiece geometry data and transmits them to the Röders machine. This allows us to check the dimensions of the workpieces immediately after machining.”

另一种选择是集成在铣刨单元中的新型 Röders RXP 950 DSH HSC 铣床:“这台机器带来了所需的高精度,可以在机器上进行全面的质量测量,”Helbock 解释道。Cimatron 根据工件几何形状数据生成与此相关的测量点,并将其传输到 Röders 机床。这使我们能够在加工后立即检查工件的尺寸。

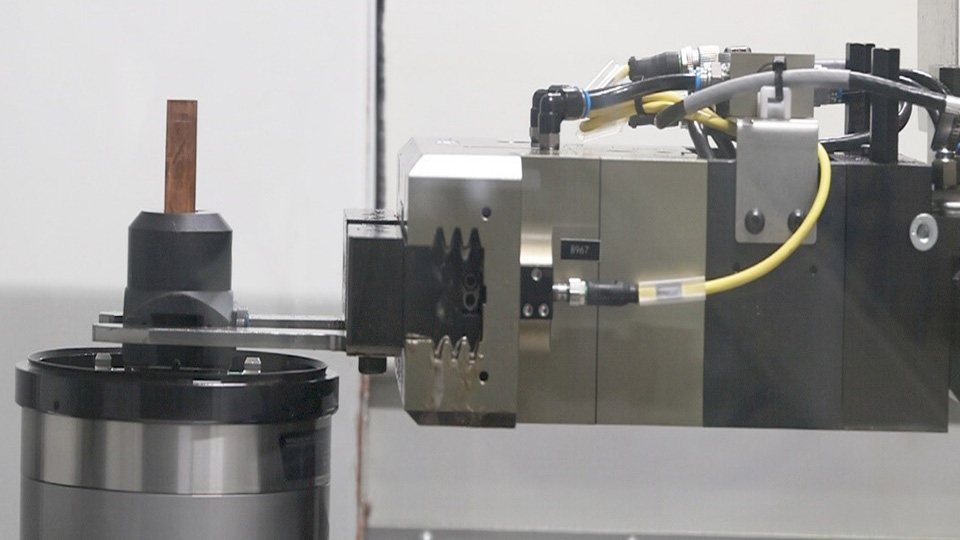

在 Alpla 工具车间的铣削单元中,一台 Kuka 机器人为两台 Hermle C 42 U 万能加工中心和一台 Röders RXP 950 DSH 高精度 HSC 铣床提供工作。- 图片:Pergler Media

This is done quickly and still in the same setup. And the deviations of the measurement results of the highly accurate Röders compared to those of the coordinate measuring machines are minimal - so they are a valid variable for evaluating the workpieces.

这是快速完成的,并且仍然在相同的设置中。与三坐标测量机相比,高精度Röders的测量结果偏差很小,因此它们是评估工件的有效变量。

Often, however, everything already fits after milling at Alpla, and corrections are usually unnecessary. But the measurement increases the reliability of the subsequent processes. Unlike measuring on the Röders machine, the coordinate measuring machines in the measuring room are currently still programmed there on site - here Helbock sees definite potential in an integration into Cimatron, because the software offers comprehensive support for the measuring machines used at Alpla.

然而,通常情况下,在 Alpla 铣削后,一切都已经适合,通常不需要进行校正。但测量提高了后续过程的可靠性。与在 Röders 机器上进行测量不同,测量室中的三坐标测量机目前仍在现场编程 - Helbock 在这里看到了集成到 Ciamtron 中的巨大潜力,因为该软件为 Alpla 使用的测量机提供了全面的支持。

用于瓶盖的复杂、高腔模具在 Alpla 模具车间的注塑模具制造中占主导地位。高可重复性对于模巢很重要 - 毕竟,无论注射到哪个型腔中,每个零件都应该完全相同。- 图片:Pergler Media

The high process reliability and stability at Alpla is systematic. The toolmakers simulate all programs and check them in Cimatron to make sure they are collision-free. And they certainly push the limits with their programs. “It happens again and again that we switch off the collision check on the machine to gain additional leeway - if the simulation from Cimatron tells us that the machining fits, we can rely on it one hundred percent,” Helbock explains. “This expands our machining options.”

Alpla 的高工艺可靠性和稳定性是系统性的。工具制造商模拟所有程序,并在Cimatron中检查它们,以确保它们没有碰撞。他们当然会用他们的程序突破极限。Helbock 解释道:“我们一次又一次地关闭机床上的碰撞检查,以获得额外的回旋余地——如果 Cimatron 的模拟告诉我们加工适合,我们可以百分之百地依赖它。“这扩展了我们的加工选择。”

The majority of the workpieces are produced in unmanned operation - including all electrodes. The tools are checked for wear and breakage with a Blum laser after each machining operation. “In the process, we have determined that if there are deviations of more than 2 mm, we will put the order on hold so that an employee can check the workpiece,” says Helbock, explaining the procedure established together with the Cimatron experts. “In the case of larger deviations, we stop the machine completely as a precaution to avoid out-of-tolerance machining or even damage to the production line. After all, the cause could be something more serious.”

大多数工件都是在无人操作的情况下生产的,包括所有电极。每次加工操作后,都会用 Blum 百隆激光器检查刀具是否磨损和破损。“在此过程中,我们已经确定,如果偏差超过 2 毫米,我们将暂停订单,以便员工可以检查工件,”Helbock 在解释与 Cimatron专家共同制定的程序时说。“在偏差较大的情况下,我们会完全停止机器,以避免加工超出公差甚至损坏生产线。毕竟,原因可能是更严重的事情。

Alpla 是开发和生产创新塑料包装解决方案的领先公司之一。其产品组合包括包装系统、瓶子、瓶盖和注塑件,适用于各行各业。- 图片:Pergler Media

Cimatron definitely still has potential that is not yet being used at Alpla. Thanks to very close and actively used contact with the software experts at Cimatron, the mold makers are constantly opening up new possibilities for themselves on the one hand, but on the other hand, with their comprehensive practical knowledge, they also help the software house to continuously improve the functions of the CAD/CAM package and expand their scope.

Cimatron肯定仍然有潜力,但Alpla尚未使用。由于与Cimatron软件专家的密切和积极联系,模具制造商一方面不断为自己开辟新的可能性,但另一方面,凭借其全面的实践知识,他们也帮助软件公司不断改进CAD/CAM软件包的功能并扩大其范围。

模具制造商直接从Cimatron生成用于Röders RXP 950 DSH质量测量的测量点。在线测量保证了后续工艺的稳定性和可靠性,并确保了注塑模具密封面的高精度。- 图片:Pergler Media

“Particularly important for us: The software experts at Cimatron always have an open ear for our wishes, suggestions and needs,” Helbock emphasizes. “They listen to us very carefully, and they also implement some of the suggestions promptly. So we get workable solutions to our challenges very quickly.” Cimatron quickly incorporates such changes into the next current release of the software - so the helpful innovations are quickly available to all Cimatron users. “In this way, all users can benefit,” Helbock sums up. “With this strategy, Cimatron recognizes current demands on the industry very quickly and can make users fit for the constantly new challenges of the competition with practice-oriented solutions.”

“对我们来说尤为重要:Cimatron 的软件专家始终倾听我们的愿望、建议和需求,”Helbock 强调说。他们非常认真地听取我们的意见,并及时实施一些建议。因此,我们很快就能为我们的挑战找到可行的解决方案。Cimatron 迅速将这些更改整合到软件的下一个当前版本中,因此所有 Cimatron 用户都可以快速获得有用的创新。“通过这种方式,所有用户都可以受益,”Helbock 总结道。“通过这一战略,Cimatron可以非常快速地认识到当前对行业的需求,并可以通过以实践为导向的解决方案使用户适应竞争中不断出现的新挑战。”

Alpla 的工人设置电极坯料并将其转移到自动铣削生产线上。其他一切都无需操作员干预 - 库卡机器人处理工件。由于在Röders上进行在线测量,保证了高过程可靠性。- 图片:Pergler Media

Cimatron generates the measuring points relevant for this from the workpiece geometry data and transmits them to the Röders machine. This allows us to check the dimensions of the workpieces immediately after machining.

Cimatron 根据工件几何形状数据生成与此相关的测量点,并将其传输到 Röders 机床。这使我们能够在加工后立即检查工件的尺寸。

Tim Helbock,Alpla Toolmaking 开发人员

Profil 普罗菲尔

Alpla Group 阿尔普拉集团

Alpla is one of the leading protagonists in the development and production of innovative plastic packaging solutions. The 22 100 employees at now 177 locations worldwide produce innovative packaging systems, bottles, closures and injection molded parts for a wide variety of industries. The tradition as a family-run company, state-of-the-art technologies Groupas well as the knowledge and commitment of the employees characterize the company and its products. Sustainability and the careful use of resources are the foundations of the company’s business activities. With more than 25 years of experience in recycling and its own recycling plants, Alpla helps to ensure that plastics remain in the material cycle.

Alpla 是开发和生产创新塑料包装解决方案的领军企业之一。目前,全球 177 个地点拥有 22100 名员工,为各行各业生产创新的包装系统、瓶子、瓶盖和注塑件。作为一家家族企业的传统,最先进的技术集团以及员工的知识和承诺是公司及其产品的特点。可持续性和谨慎使用资源是公司业务活动的基础。凭借超过 25 年的回收经验和自己的回收工厂,Alpla 帮助确保塑料留在材料循环中。

FOCUS 重点

Quality measurements on the machine

机器上的质量测量

The CAD/CAM software Cimatron enables very precise measurement of specific dimensions on correspondingly accurate CNC machines. Different measuring cycles are available for this purpose. At Alpla, the toolmakers measure both electrodes and hard-milled workpieces on a Röders RXP 950 DSH - it provides the correspondingly required accuracy ex works. Measurement results on the part that are outside the tolerance are marked accordingly on the automatically generated measurement report. In addition, each tool is checked for wear and breakage after machining. Based on the measurement results, different follow-up actions are triggered so that as few downtimes as possible occur.

CAD/CAM软件Cimatron可以在相应精确的数控机床上非常精确地测量特定尺寸。为此,可以使用不同的测量周期。在Alpla,工具制造商在Röders RXP 950 DSH上测量电极和硬铣削工件 - 它在出厂时提供了相应的精度。超出公差的零件的测量结果会在自动生成的测量报告上相应地标记。此外,每把刀具在加工后都会检查磨损和破损情况。根据测量结果,触发不同的后续操作,以尽可能减少停机时间。

VIEWPOINT 观点

From practice - for practice

从实践 - 为了实践

Close contact between users and software developers is a great advantage, especially with a CAD/CAM system like Cimatron - for all sides. If the software developers have an open ear for sensible suggestions and also process them quickly, the users promptly receive practicable solutions to their challenges. And nothing better can happen to a software company than committed and experienced users pointing out the potential for improvements, enhancements and additions. A partnership at eye level that benefits all users of the CAD/CAM package.

用户和软件开发人员之间的密切联系是一个很大的优势,特别是对于像 Cimatron 这样的 CAD/CAM 系统 - 适用于各方。如果软件开发人员对明智的建议持开放态度并快速处理它们,用户就会迅速收到解决其挑战的切实可行的解决方案。对于一家软件公司来说,没有什么比忠诚和有经验的用户指出改进、增强和补充的潜力更好的了。与视线齐平的合作伙伴关系使 CAD/CAM 软件包的所有用户受益。