Officine Drag - Creative Craftsmanship

Officine Drag - 创意工艺

Officine Drag SRL Finds a Perfect Fit with Cimatron.

Officine Drag SRL 与 Cimatron 完美契合。

With the right technology, resourcefulness, and expertise, even a smaller mold-making company can help to transform their customers ideas into reality.

凭借正确的技术、足智多谋和专业知识,即使是较小的模具制造公司也可以帮助将客户的想法变为现实。

Officine Drag Srl (www.officinedragsrl.it) has been operating for more than two decades in the plastic mold industry, applying their creative methodology in developing tools for industrial production in diverse commodity sectors. The company aims to grow their trade while holding true to the craftsmanship that has always distinguished it from its competitors.

Officine Drag Srl ( www.officinedragsrl.it) 在塑料模具行业已经运营了二十多年,将他们的创新方法应用于开发各种商品行业的工业生产工具。该公司的目标是发展他们的贸易,同时坚持始终将其与竞争对手区分开来的工艺。

As Managing Director Felicetta Gabrielloni points out: “For Officine Drag, craftsmanship means attention to detail, quality of raw materials, and experimental research and development, but it also defines a flexibility and willingness to meet customer requirements. Our commitment, teamwork and careful organization has allowed us to grow positively by expanding into new markets.“

正如总经理Felicetta Gabrielloni所指出的:“对于Officine Drag来说,工艺意味着对细节、原材料质量和实验研发的关注,但它也定义了满足客户要求的灵活性和意愿。我们的承诺、团队合作和精心的组织使我们能够通过拓展新市场而实现积极增长。

A highly prized service

备受推崇的服务

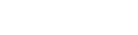

Based in the Marche region, between the Apennine Mountains and the Adriatic Sea, Officine Drag Srl handles all stages of the development and manufacturing process for single and multicavity molds, including gas-assisted and bi-tri color molds. In order to guarantee a quality outcome, Officine Drag also performs pre-production testing to verify the efficiency and functionality of the mold itself. If necessary, they will run mold samples or small pre-series production cycles. From their start in serving high-end homeware accessory industry, their customer base has now extended to other sectors such as packaging, building, and automotive.

Officine Drag Srl 总部位于亚平宁山脉和亚得里亚海之间的马尔凯地区,负责单腔和多腔模具的开发和制造过程的所有阶段,包括气体辅助模具和双色模具。为了保证质量结果,Officine Drag还进行生产前测试,以验证模具本身的效率和功能。如有必要,他们将运行模具样品或小的预批量生产周期。从他们最初服务于高端家居用品配件行业,他们的客户群现在已经扩展到其他行业,如包装、建筑和汽车。

“Our team is composed of young but experienced technicians, with a deep know-how and a strong skillset gained through the continuous training that the company provides; they are able to face any professional challenge. We strongly believe in the development of new technologies, and this is why we embraced the smart automation philosophy of Industry 4.0 from the very beginning. When working with the customer, the functional and aesthetic characteristics of the product are already defined, but the technical solution, combining both economic feasibility and the production goals of the mold have to be set to meet the customers expectations. We guarantee after-sales service and extraordinary punctuality in terms of project delivery. This last point is taken very seriously within the company: if we delay a delivery, we self-apply a penalty for each week of delay!

“我们的团队由年轻但经验丰富的技术人员组成,他们拥有深厚的专业知识和强大的技能,通过公司提供的持续培训获得;他们能够面对任何专业挑战。我们坚信新技术的发展,这就是为什么我们从一开始就接受工业 4.0 的智能自动化理念。在与客户合作时,产品的功能和美学特征已经确定,但必须设定技术解决方案,结合模具的经济可行性和生产目标,以满足客户的期望。我们保证售后服务和项目交付方面的非凡准时性。最后一点在公司内部得到了非常认真的对待:如果我们延迟交货,我们每延迟一周就会自行受到处罚!

Officine Drag SRL制造不同类型的模具,从热塑性注塑到吹塑成型,包括两种或三种材料的复杂模具,如塑料和橡胶成型。

To ensure we can communicate the project status at any point, we use the Gantt project management tool to show all production activities (tasks or events) displayed against the project timeline. We share the status reports with the customer every week and send photos of the mold under construction so everyone can see the progress update. This is a much appreciated service, especially when working with clients in other countries such as Germany, Spain, and France. It generates confidence and gives our customers peace of mind.“

为了确保我们可以随时传达项目状态,我们使用甘特图项目管理工具来显示根据项目时间表显示的所有生产活动(任务或事件)。我们每周与客户分享状态报告,并发送正在建造的模具的照片,以便每个人都能看到进度更新。这是一项非常受欢迎的服务,尤其是在与德国、西班牙和法国等其他国家的客户合作时。它能产生信心,让我们的客户高枕无忧。

Multi-Axis Machining 多轴加工

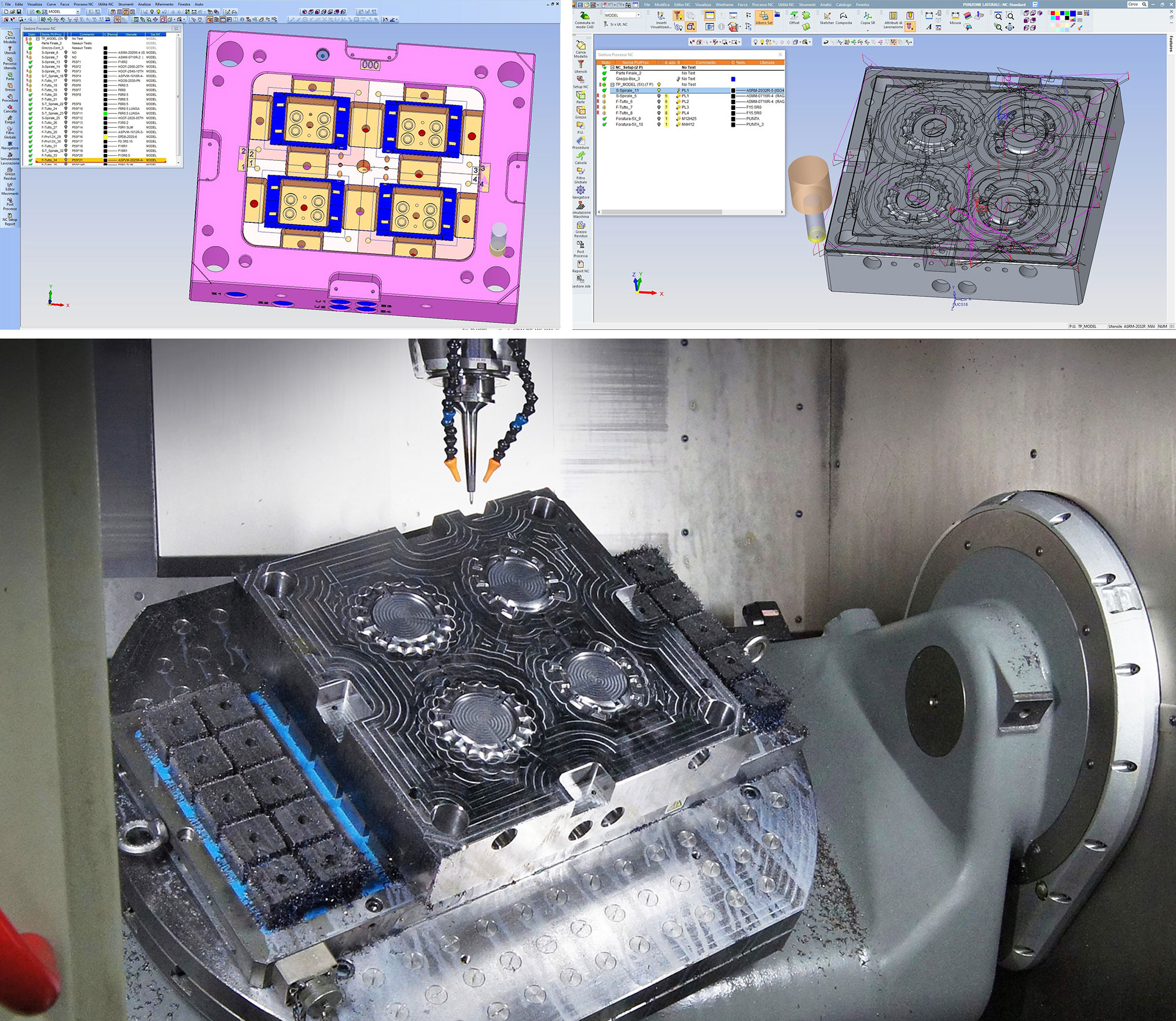

Officine Drag has a number of medium to large machine tools including a HERMLE C 650, SACHMAN TS10, REMA CONTROL LT5-25, and many others so it can handle manufacturing molds up to 8 tons. “We typically already know how to do what is asked of us, but unusual challenges are always welcome in order to offer real value to the customer. We can build different types of molds depending on the relevant technology, from thermoplastic injection to blow molding on a traditional press. Particularly complex are molds with two or three materials, such as molding plastic and rubber, which have unique constraints or rotary table tansfers.

Officine Drag 拥有许多大中型机床,包括 HERMLE C 650、SACHMAN TS10、REMA CONTROL LT5-25 等,因此它可以处理重达 8 吨的模具制造。“我们通常已经知道如何做要求我们做的事情,但为了向客户提供真正的价值,我们总是欢迎不寻常的挑战。我们可以根据相关技术制造不同类型的模具,从热塑性注塑到传统压力机上的吹塑成型。特别复杂的是具有两种或三种材料的模具,例如具有独特约束的塑料和橡胶成型模具或转盘鞣制。

For example, when using two materials, a nozzle injects plastic into a mold in the first cycle. The mold is then automatically rotated and a different type of plastic is injected into the mold from a second nozzle to produce the final product. In these situations we have many years of experience and always achieve a result within budget.“ Thus beautiful products come to life, designed more and more for technical applications. The importance of aesthetics is joined by the need for absolute precision.

例如,当使用两种材料时,喷嘴在第一个循环中将塑料注入模具中。然后模具自动旋转,从第二个喷嘴将不同类型的塑料注入模具以生产最终产品。在这些情况下,我们拥有多年的经验,并且始终在预算范围内取得成果。因此,美丽的产品栩栩如生,越来越多地为技术应用而设计。美学的重要性与对绝对精度的需求相结合。

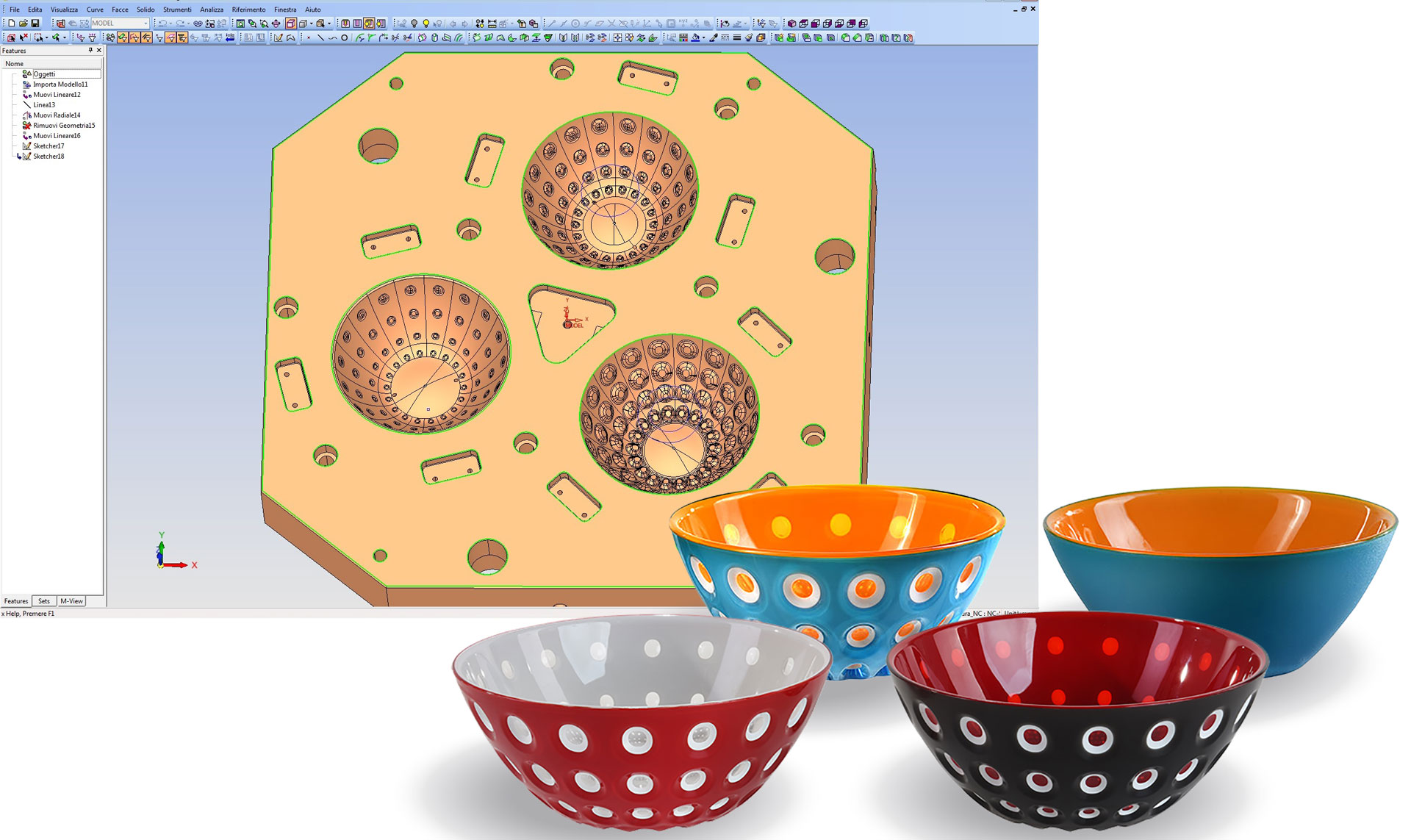

Officine Drag believes strongly in investing in state of the art technology. This includes the deployment of Cimatron CAD/CAM for programming all CNC machines for drilling, 2.5 and 5-axis operations. Cimatron provides powerful analysis tools and simulation, as Export Area Manager Federico Salvatelli confirms, “Most of our CAM work is done with three-axis operations, or positional five axis (3+2). However, we also have the ability to run five axes continuously when the geometry of the mold requires it. In these cases the on-screen simulation and verification is almost mandatory to be sure that the path is safe before running the machine.

Officine Drag坚信投资最先进的技术。这包括部署Cimatron CAD/CAM,用于对所有数控机床进行钻孔、2.5轴和5轴操作编程。Cimatron 提供强大的分析工具和仿真功能,正如出口区域经理 Federico Salvatelli 所证实的那样,“我们的大部分 CAM 工作都是通过三轴操作或定位五轴 (3+2) 完成的。但是,当模具的几何形状需要时,我们也能够连续运行五个轴。在这些情况下,屏幕上的模拟和验证几乎是强制性的,以确保在运行机器之前路径是安全的。

The simulation in Cimatron includes not only the actual machining, but also the entire machine kinematics, so that any potential issues with fixtures, workpiece, tool, or tool holders can be detected immediately. Once the toolpaths have been verified, we often launch unattended semi-finishing and finishing operations, with the confidence that there will be no issues on the machine.“

Cimatron 的仿真不仅包括实际加工,还包括整个机床运动学,因此可以立即检测到夹具、工件、刀具或刀柄的任何潜在问题。一旦刀具路径得到验证,我们通常会启动无人值守的半精加工和精加工操作,并确信机床不会出现任何问题。

Officine Drag 拥有多台大中型机床,包括 HERMLE C 650、SACHMAN TS10、REMA CONTROL LT5-25,可处理重达 8 吨的模具制造。

This is a high-efficiency technology that promises to cut machining times significantly

这是一项高效率技术,有望显著缩短加工时间

Felicetta Gabrielloni,Officine Drag SRL 董事总经理

Process Automation 过程自动化

High automation is in fact one of the characteristics of the Cimatron system. The intent is to give the designer or programmer the ability to process entire phases of the operation workflow by using user-defined templates that load parameters and rules from the centralized database.

事实上,高自动化是Cimatron系统的特点之一。其目的是使设计人员或程序员能够使用用户定义的模板处理操作工作流的整个阶段,这些模板从集中式数据库加载参数和规则。

This “intelligent” database can adapt over time and can be used by anyone to achieve the same results, following proven and tested company standards. By establishing plant-wide company standards, this ensures that, from user to user, job to job, you are able to produce consistent results and high-quality tooling.

这个“智能”数据库可以随着时间的推移而调整,任何人都可以使用,以达到相同的结果,遵循经过验证和测试的公司标准。通过建立全厂范围的公司标准,这确保了从用户到用户、从作业到作业,您能够产生一致的结果和高质量的工具。

Worthy of note, for example, is the accuracy of the residual stock after each roughing pass: “When using Cimatron, we noted the drastic reduction in air retract movements. These are only a few seconds per move, but when adding them up at the end of the week or at the end of the month, they equate to values that are no longer negligible, especially on machines that are a little older and do not run at especially high speeds.“

例如,值得一提的是每次粗加工后剩余毛坯的精度:“使用Cimatron时,我们注意到空气退刀运动的急剧减少。这些每次移动只有几秒钟,但是当在周末或月底将它们加起来时,它们等同于不再可以忽略不计的值,尤其是在稍旧且运行速度不是特别高的机器上。

In the near future, Officine Drag is planning to implement the use of form tools such as barrel cutters. When using these new tools for finishing operations, step-overs and step-downs are very large compared to those of bull nose cutters. Typically, most machining time is spent using tools to finish surfaces that require small depths of cut and step-overs (0.05 to 0.2mm).

在不久的将来,Officine Drag计划实施使用钢桶切割机等成型工具。当使用这些新工具进行精加工操作时,与牛鼻切割机相比,跨步和降压非常大。通常,大多数加工时间都花在使用刀具精加工需要小切削深度和跨距(0.05 至 0.2 毫米)的表面上。

However, barrel tools can offer up to 8x greater depth of cut and step-over, and improved surface finish due to fewer cusps compared to traditional tooling. “We have already seen Cimatron is able to support these tools. This is a high-efficiency technology that promises to cut machining times significantly. Our plan is to adopt this type of high-performance tooling and use them on our HERMLE C 650 machining centre with the support of excellent CAM!“

然而,与传统工具相比,桶形刀具可以提供高达 8 倍的切削深度和跨步,并且由于刀尖更少,因此表面光洁度更高。“我们已经看到 Cimatron 能够支持这些工具。这是一项高效率技术,有望显著缩短加工时间。我们的计划是采用这种高性能刀具,并在出色的CAM的支持下,在我们的HERMLE C 650加工中心上使用它们!